Les avantages de l'impression 3D SLA avec 3DPROD

Précision

Rapidité

Personnalisation

Qu’est ce que la Stéréolithographie SLA ?

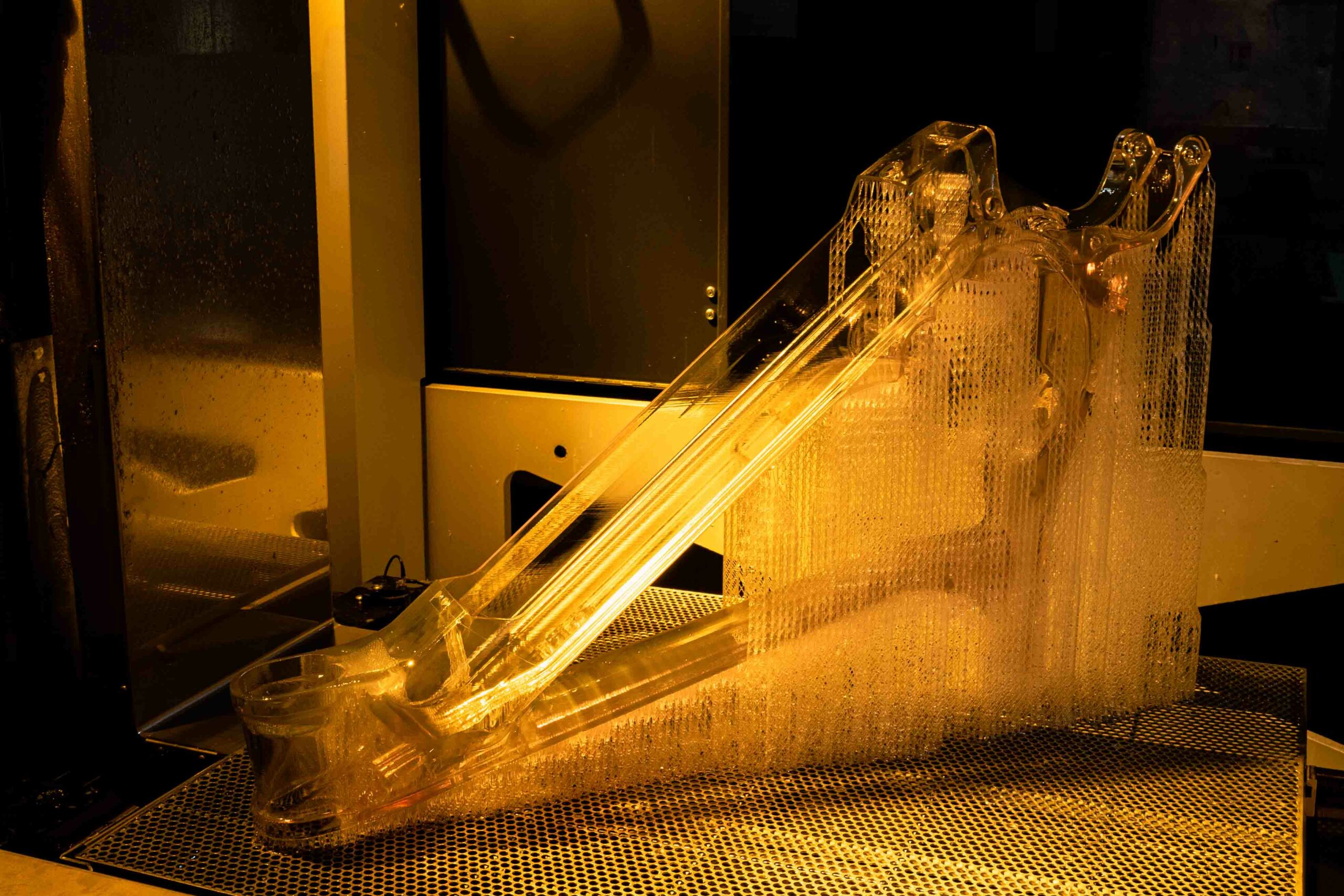

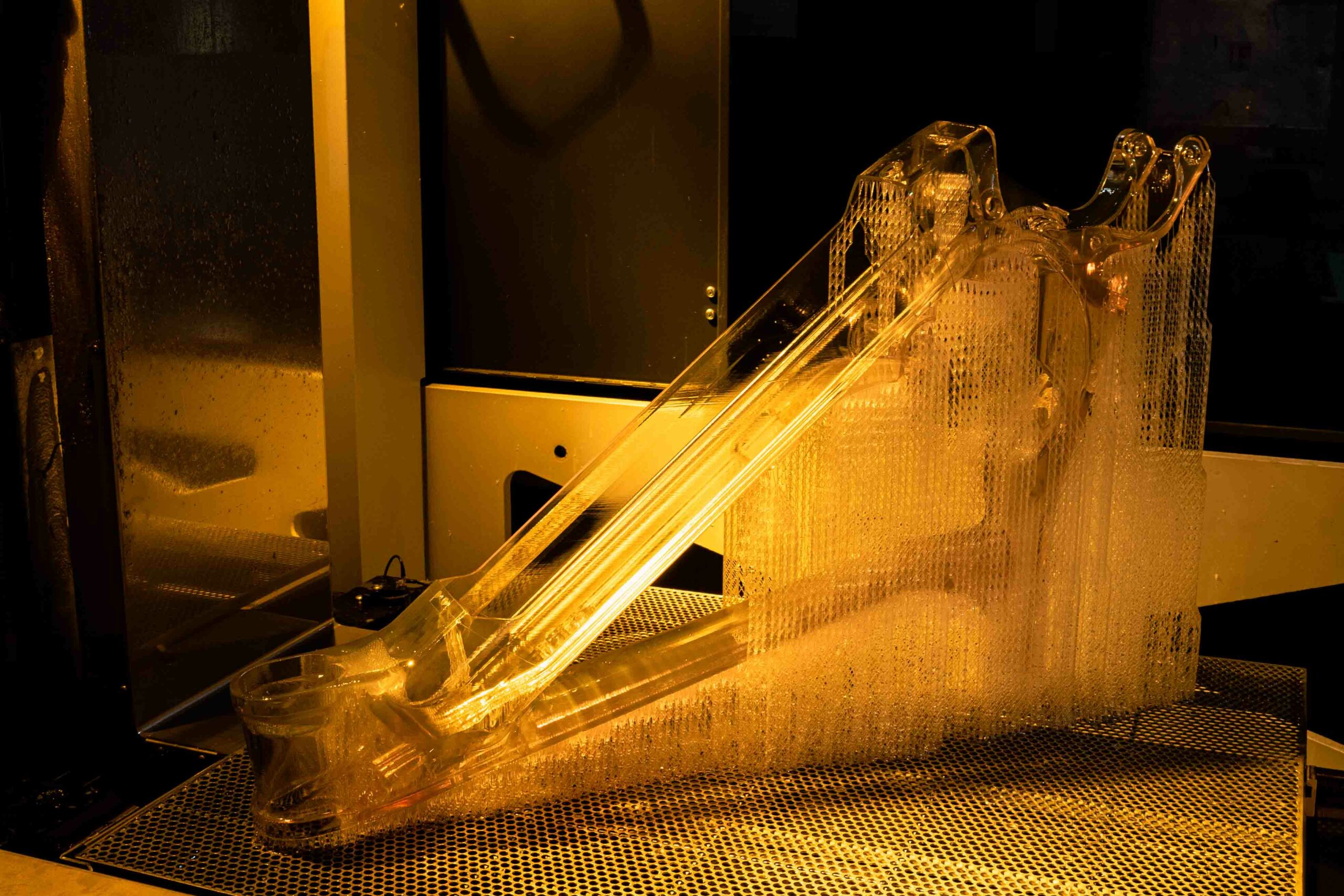

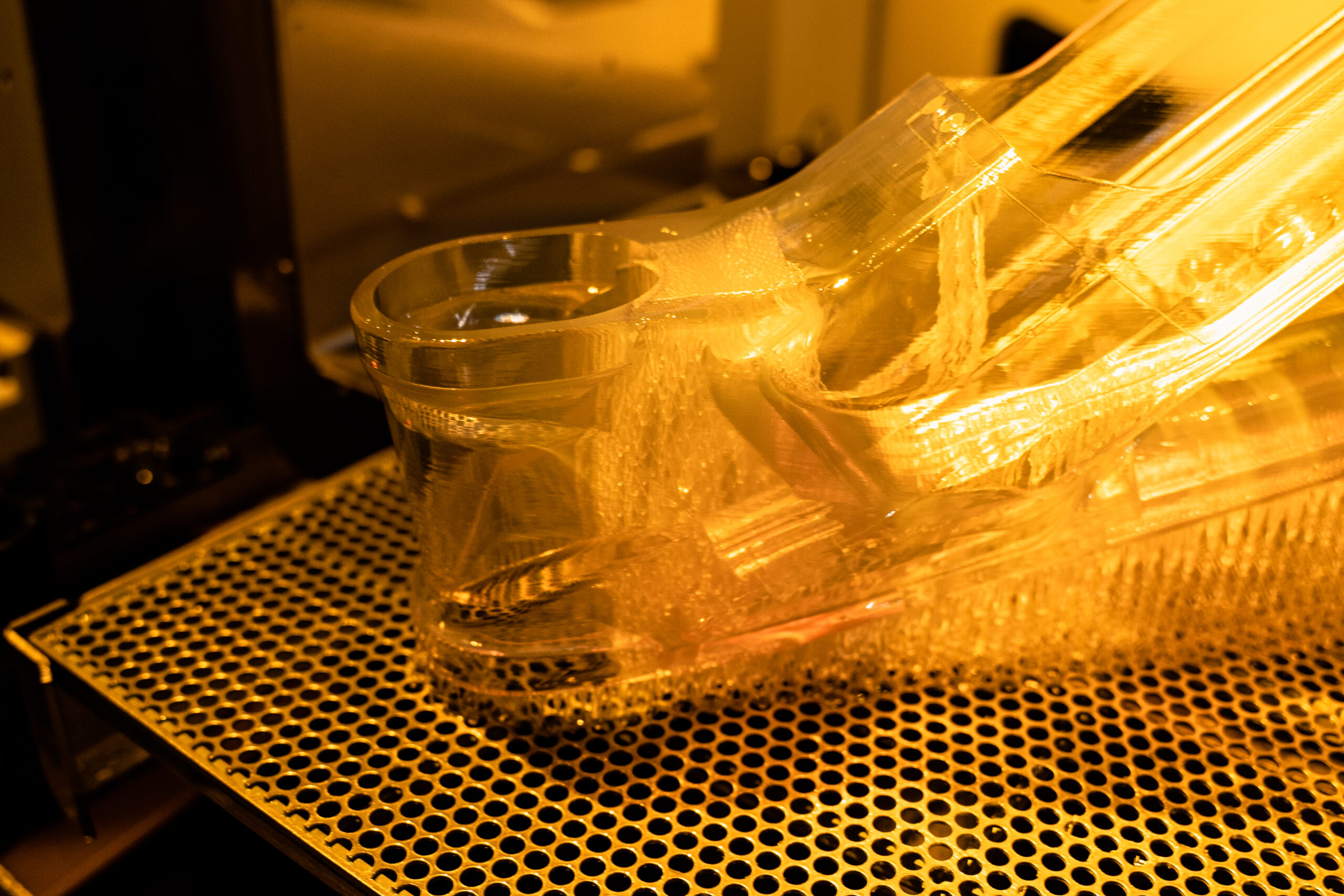

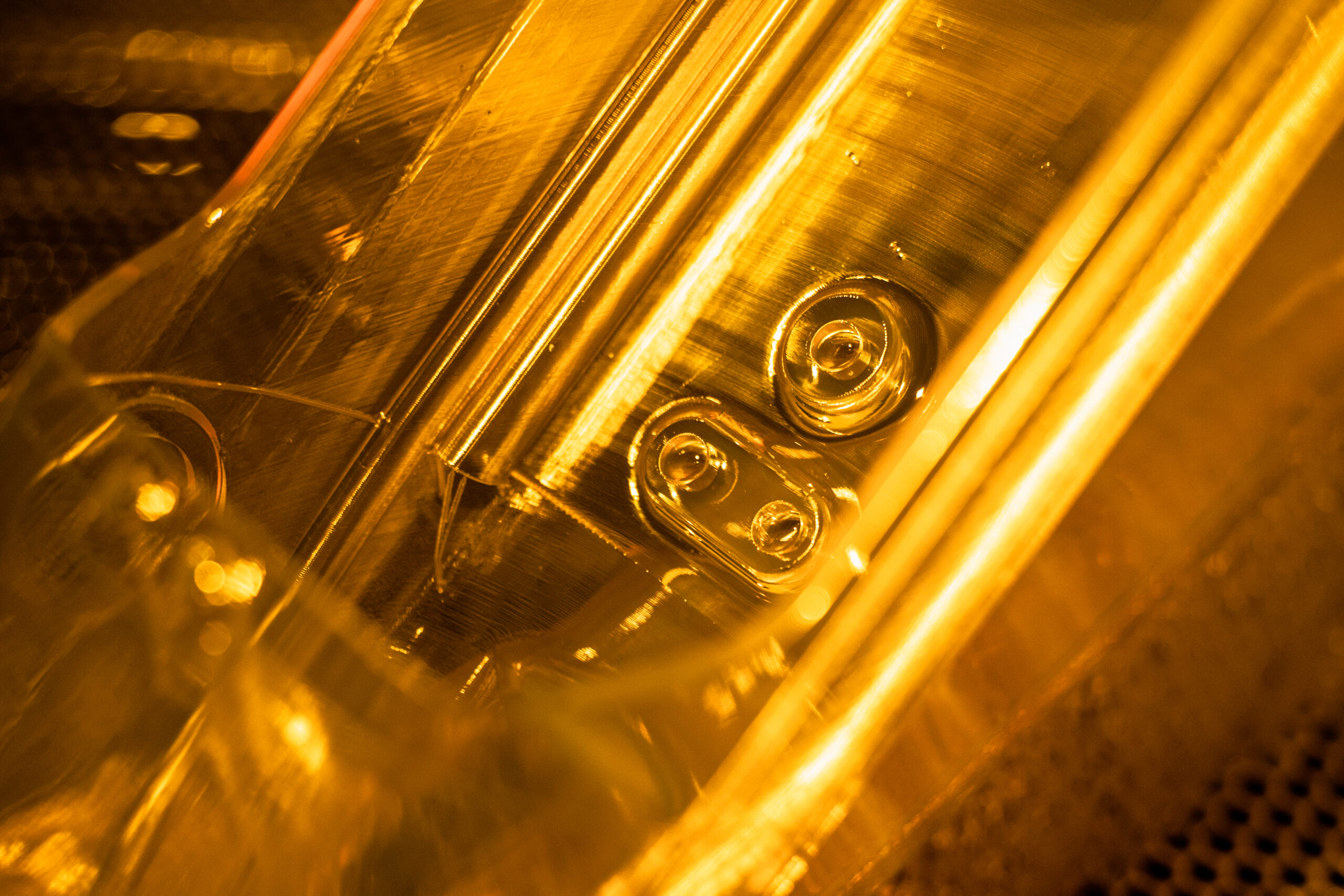

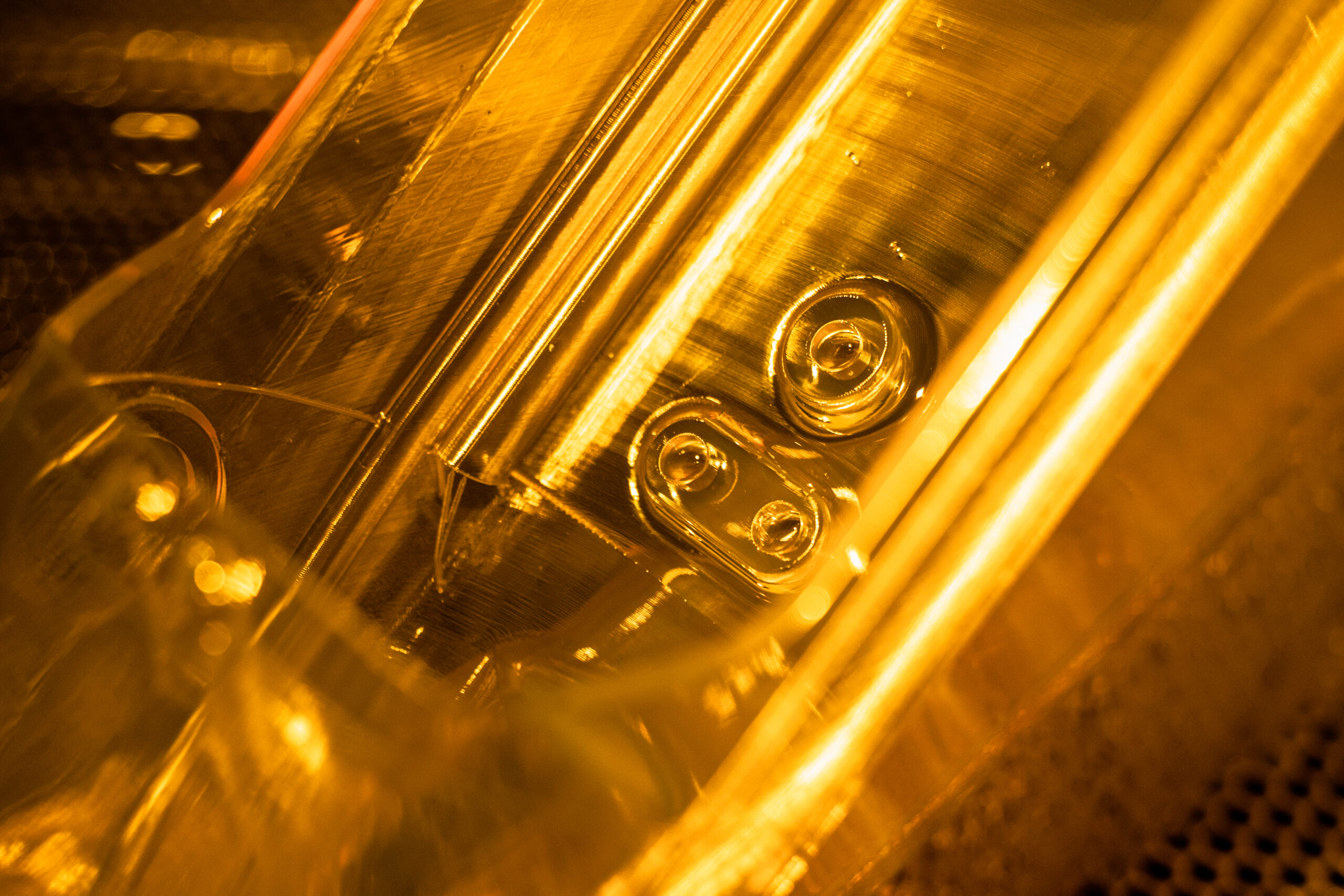

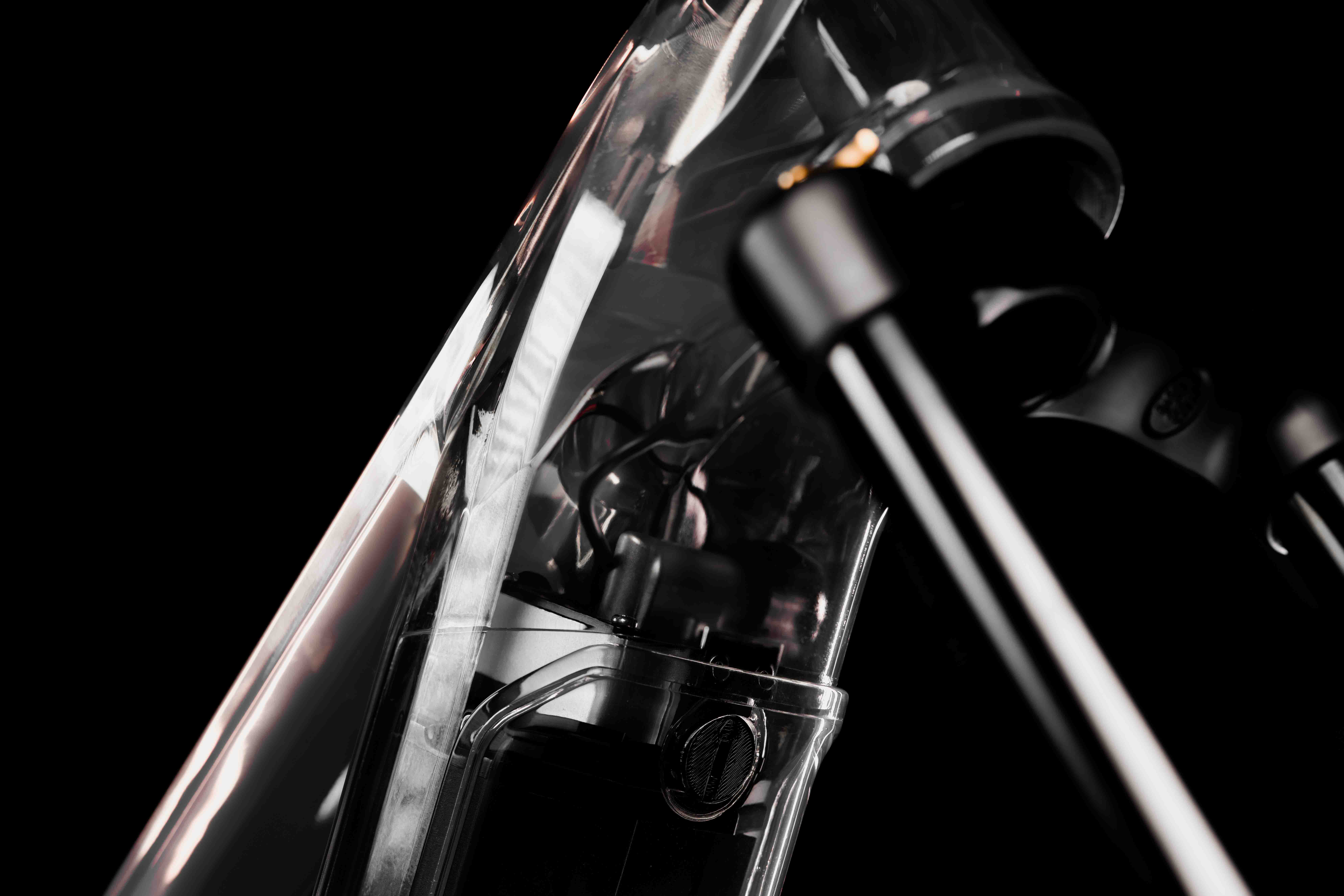

La stéréolithographie, souvent abrégée en SLA, est une méthode d’impression 3D qui utilise la photopolymérisation pour créer des objets en trois dimensions à partir d’une résine réactive aux rayons UV. Cette résine est solidifiée progressivement par un laser, couche après couche. Cette méthode offre une qualité d’impression parmi les plus élevées parmi les technologies d’impression actuelles

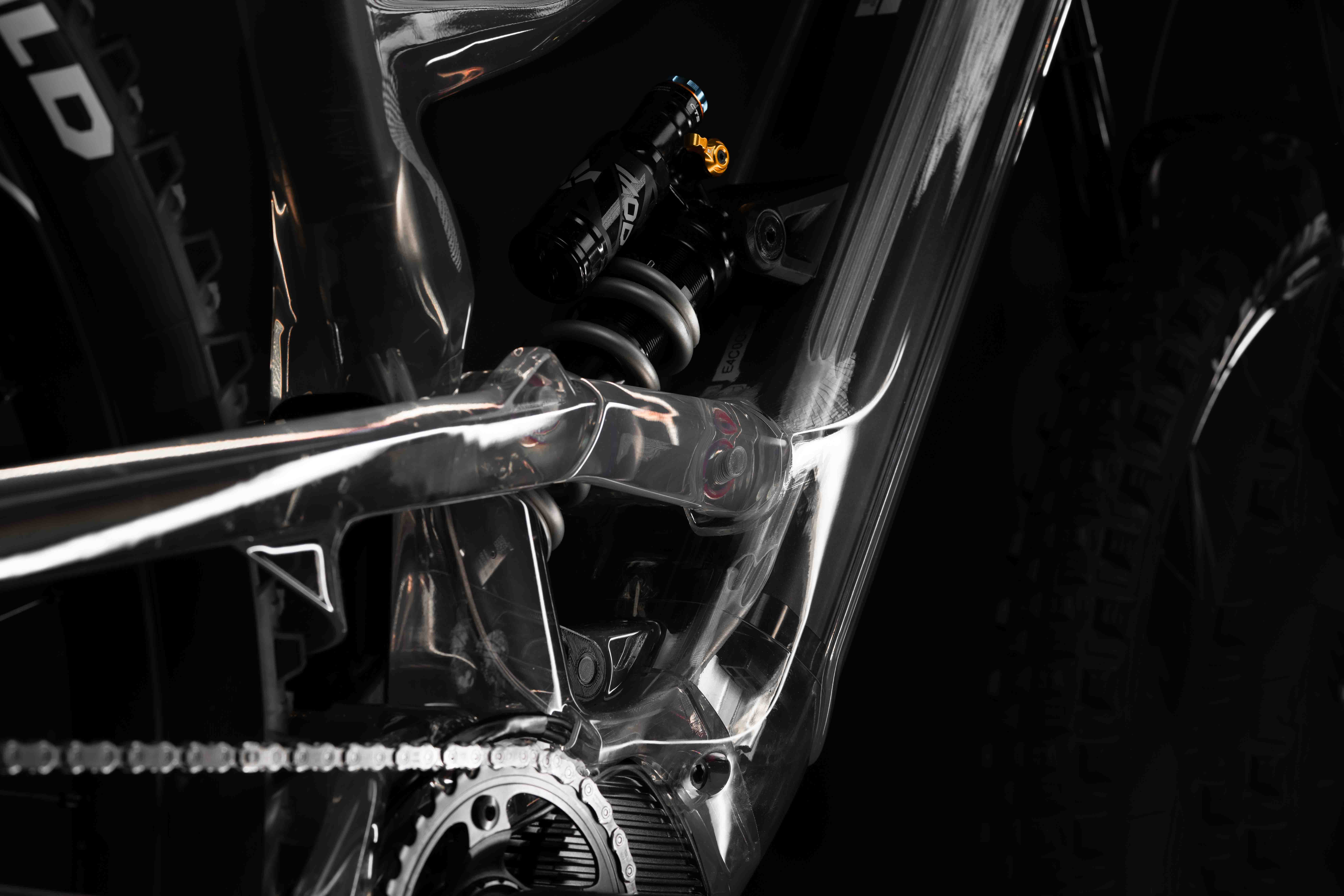

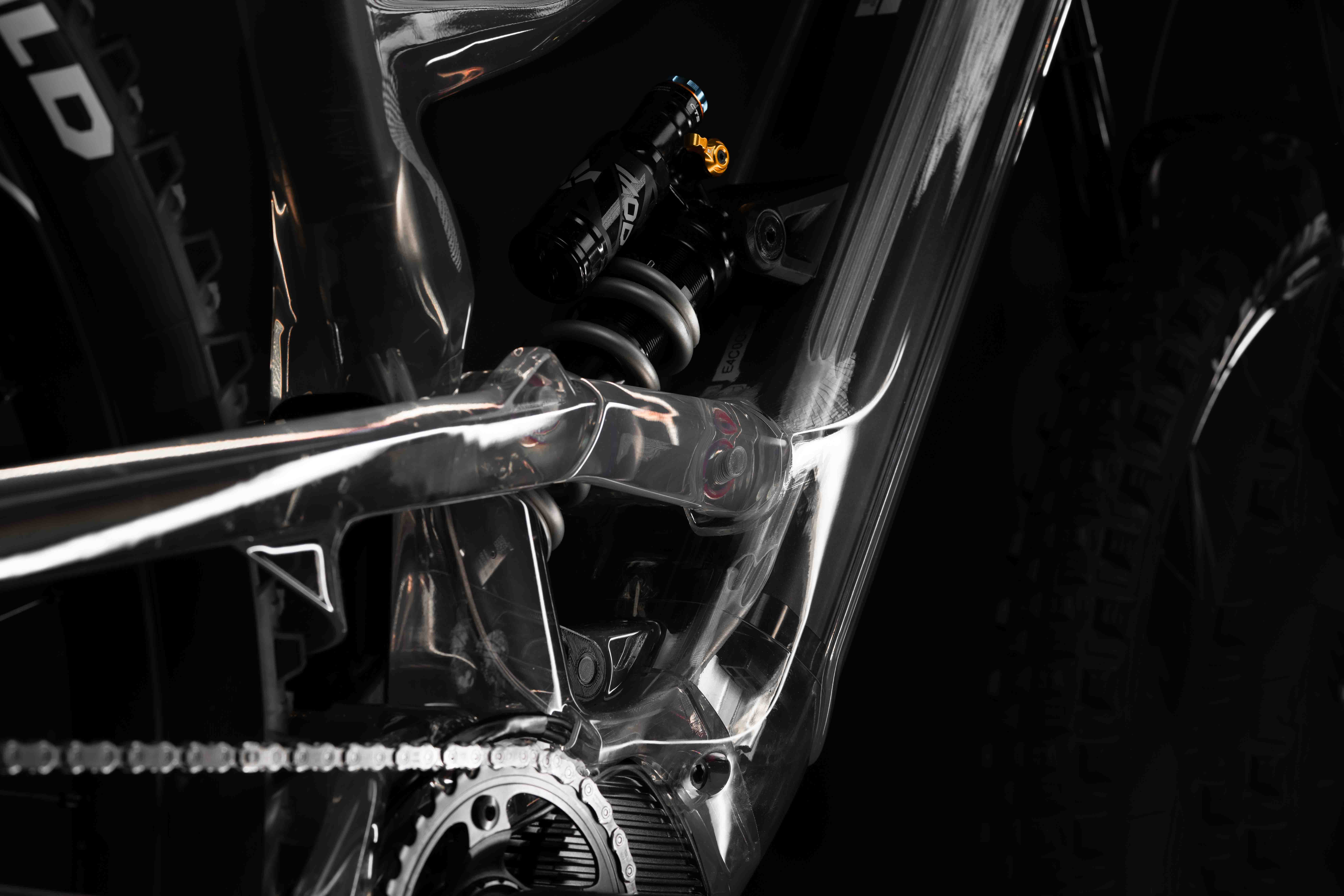

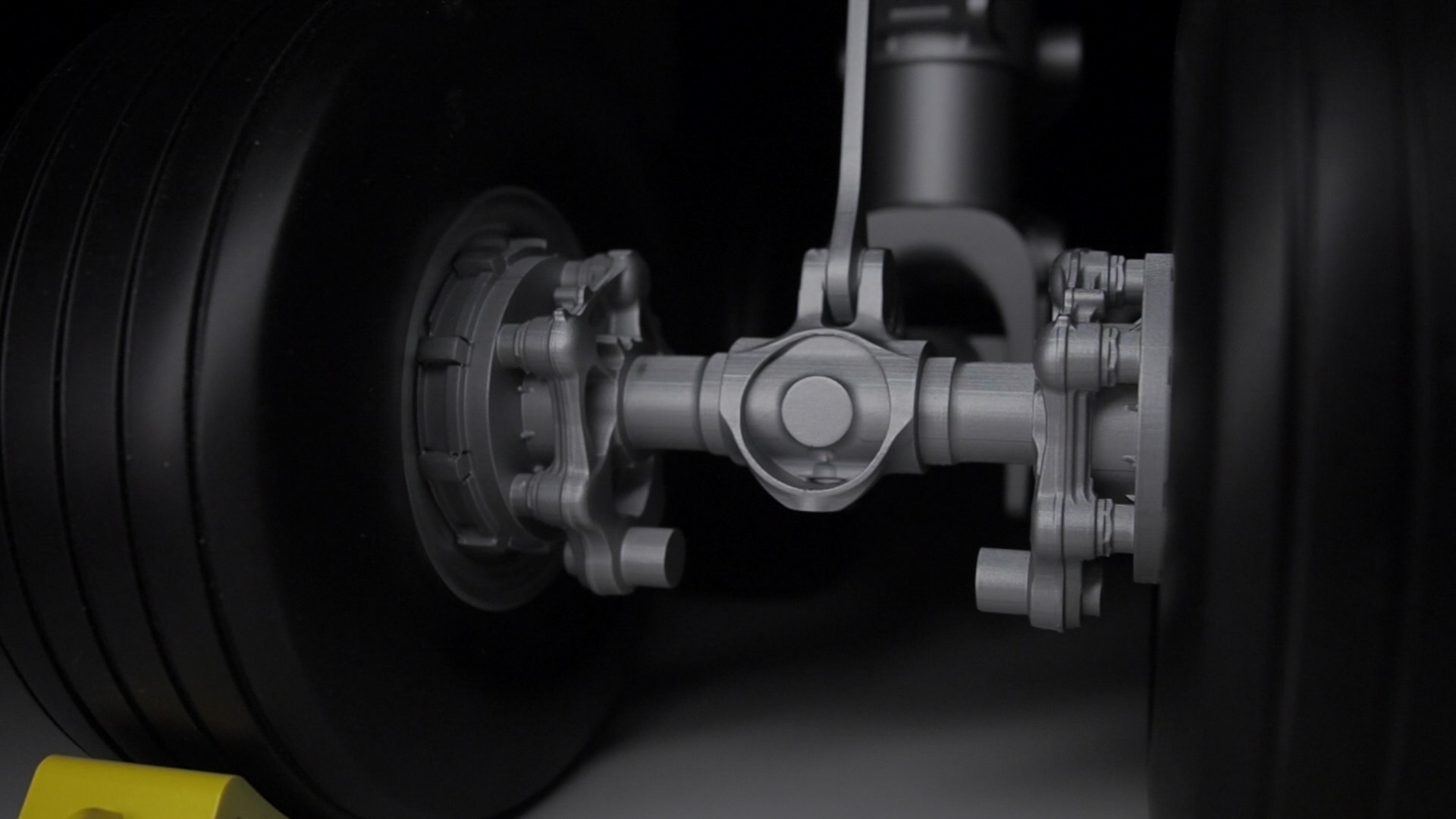

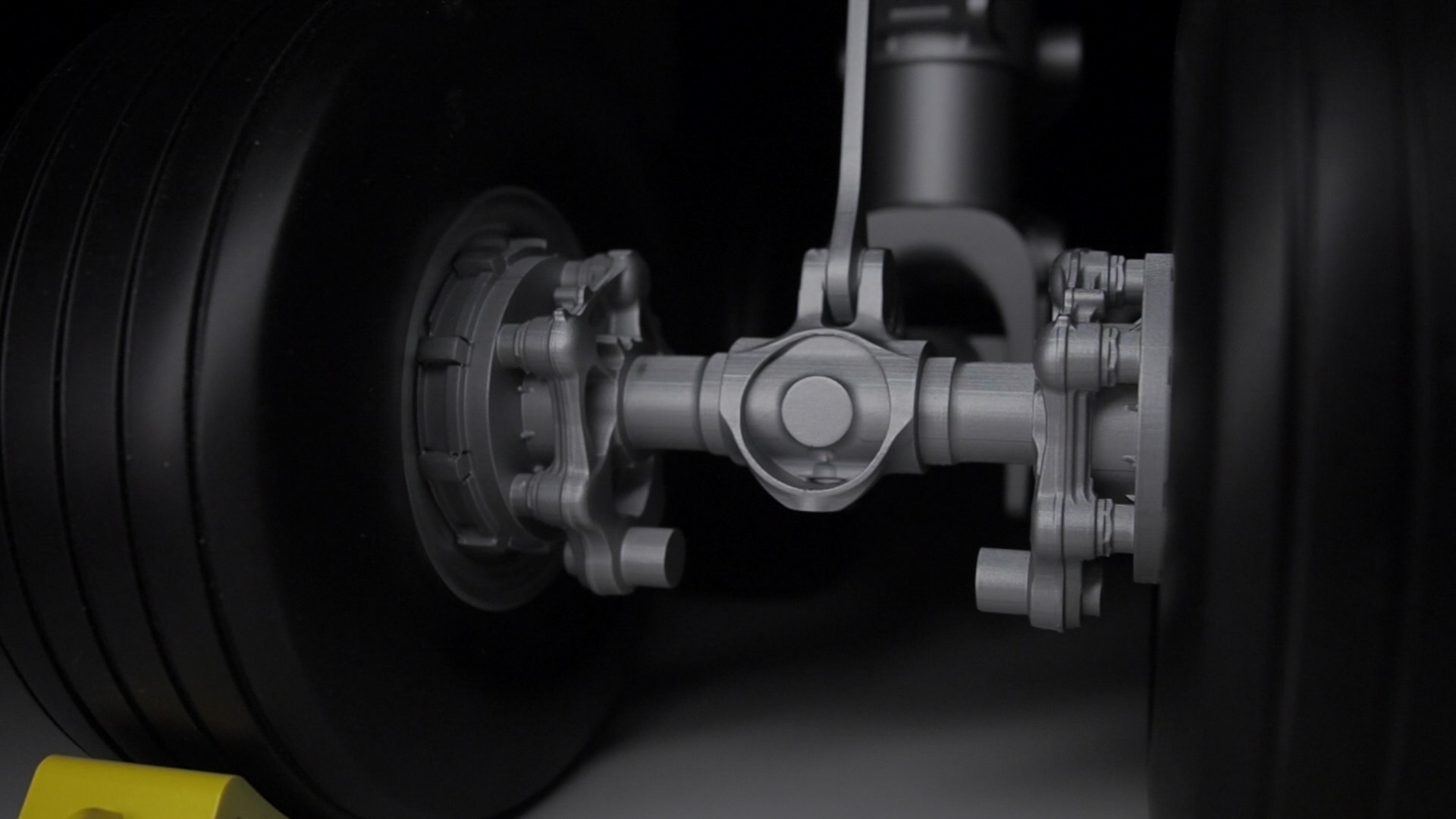

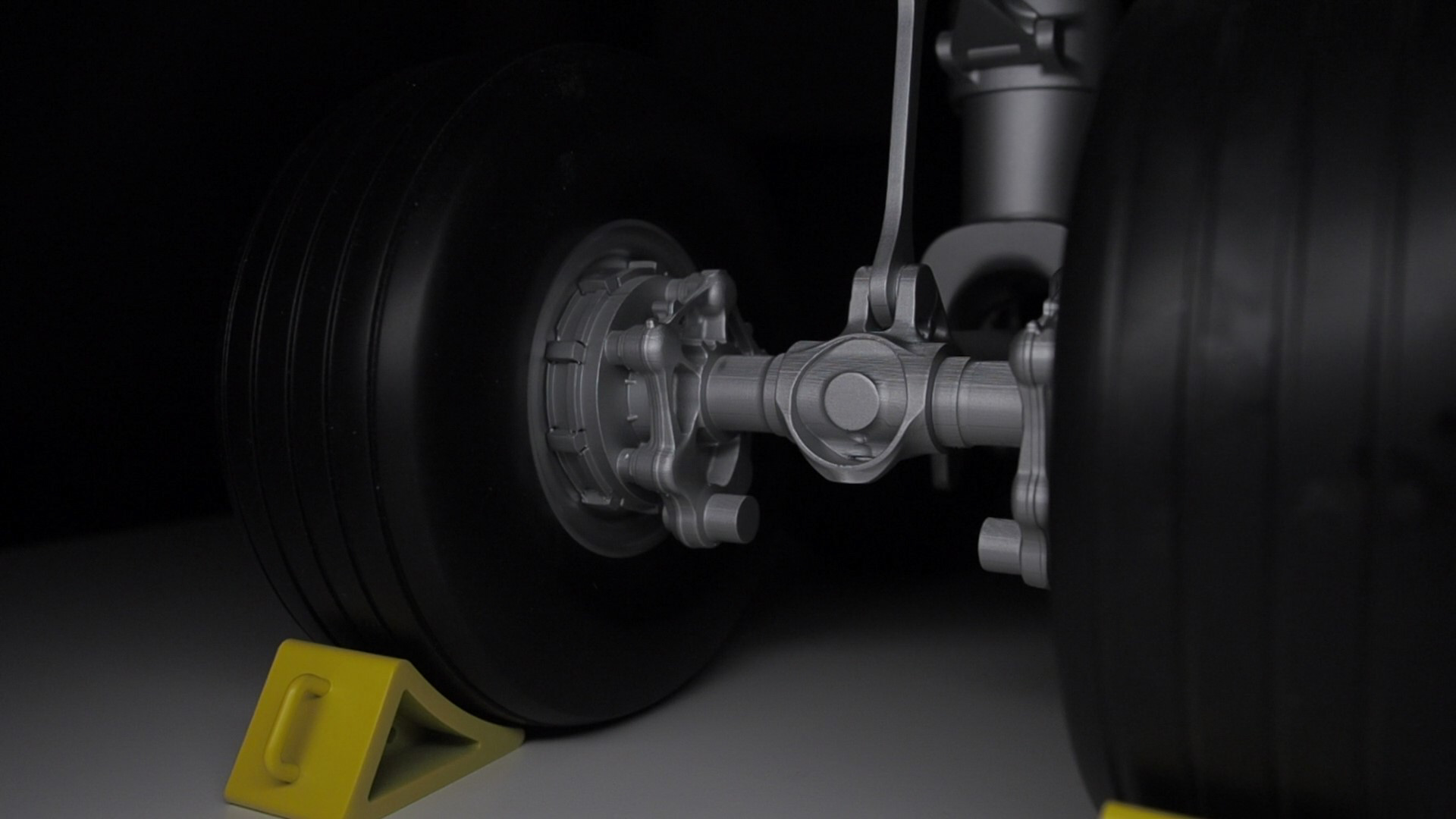

la stéréolithographie est utilisée dans de nombreux secteurs industriels pour la production de pièces fonctionnelles, de prototypes de démonstration et de modèles.

Elle est particulièrement utile dans les industries qui exigent une haute précision et une grande qualité de surface, ainsi que celles qui nécessitent la production de pièces aux géométries complexes ou demandant une production à grande échelle.

Les avantages de la Stéréolithographie

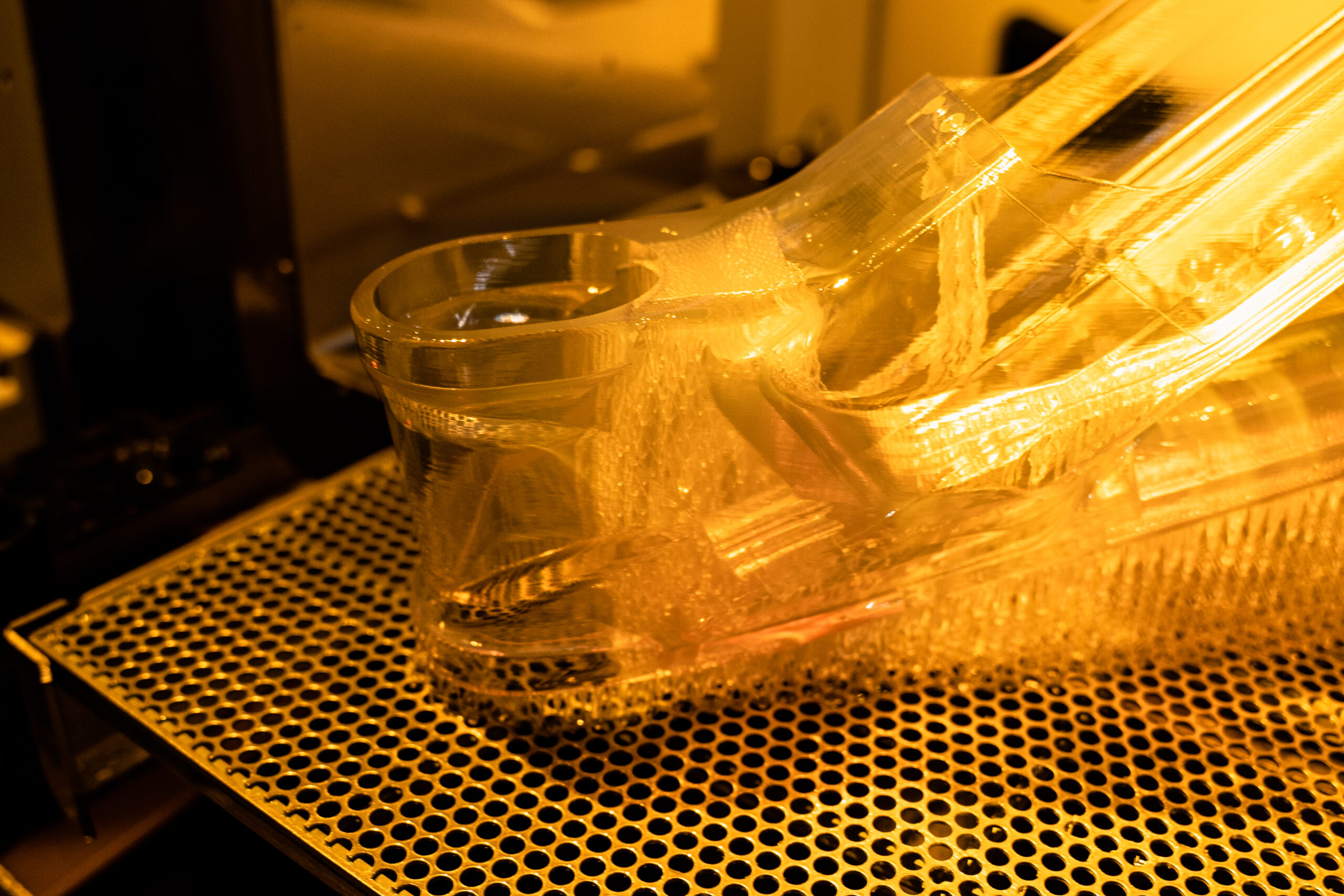

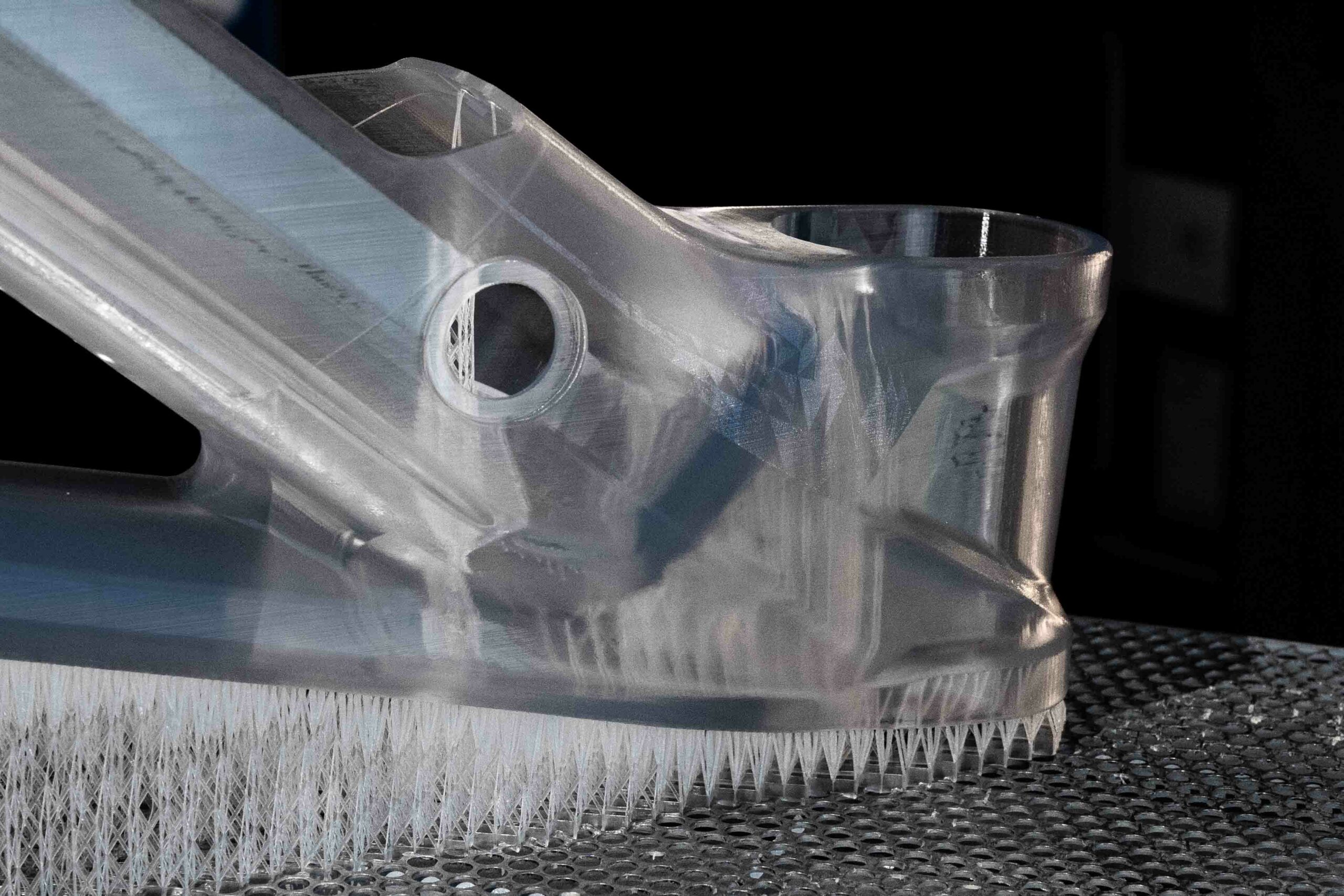

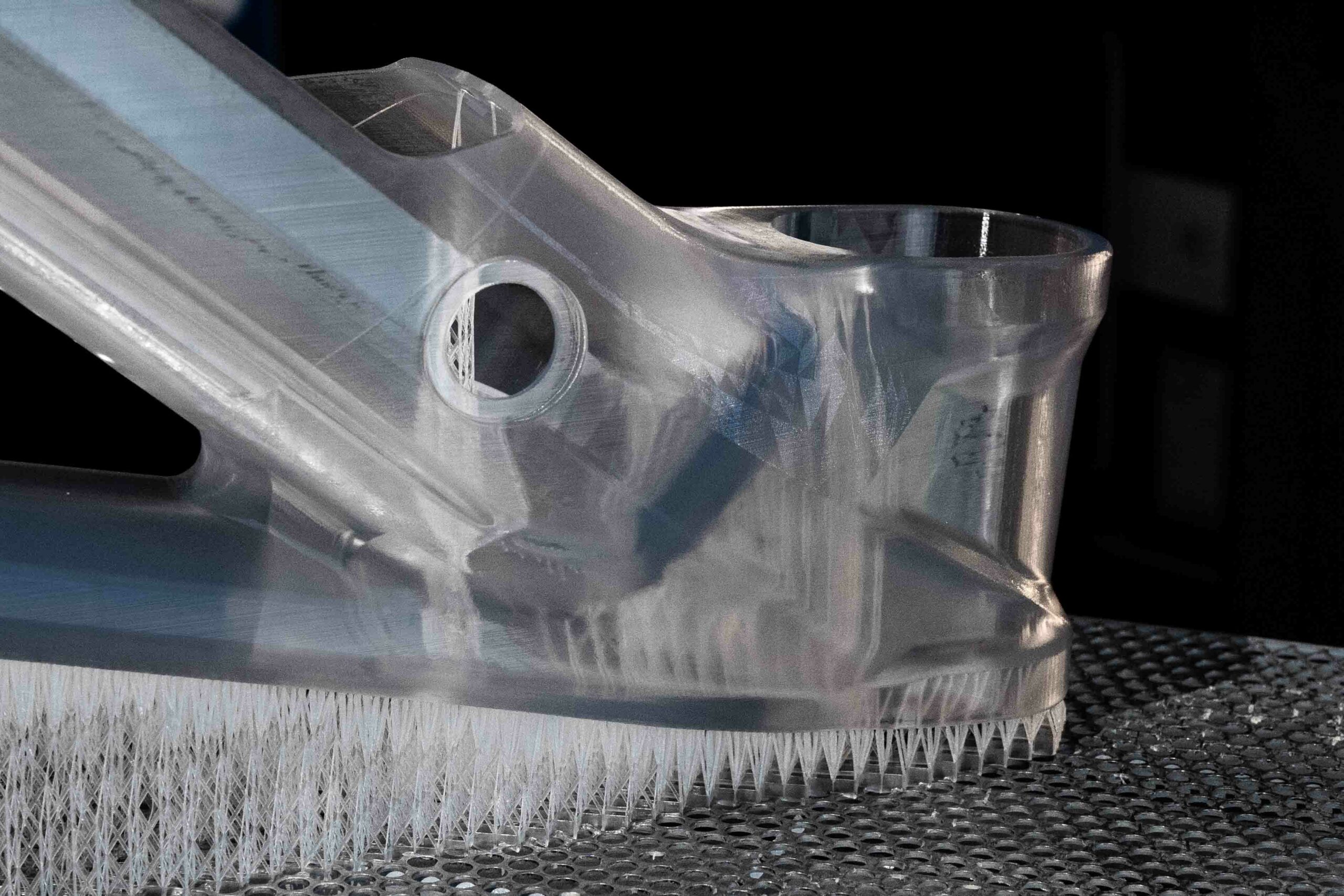

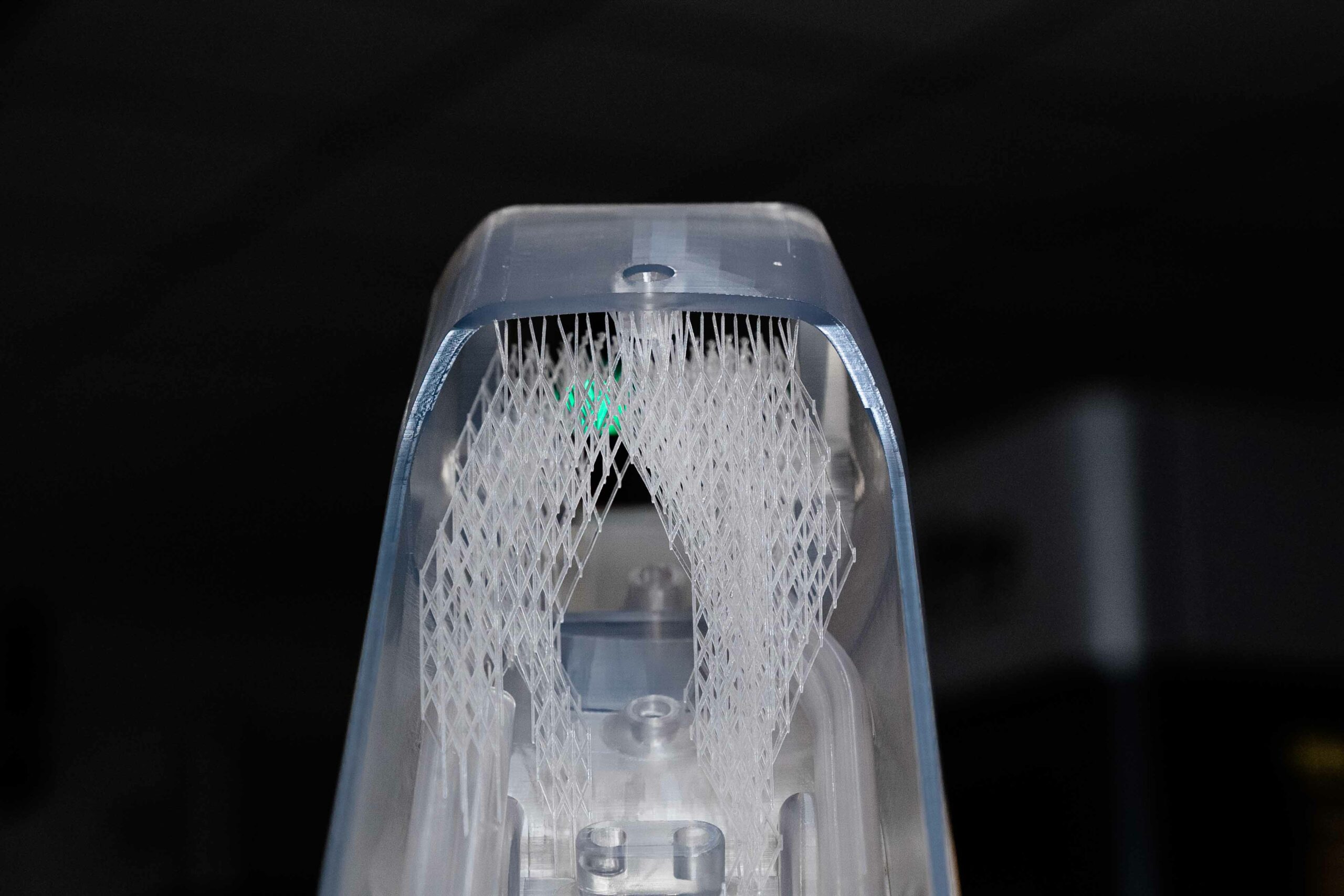

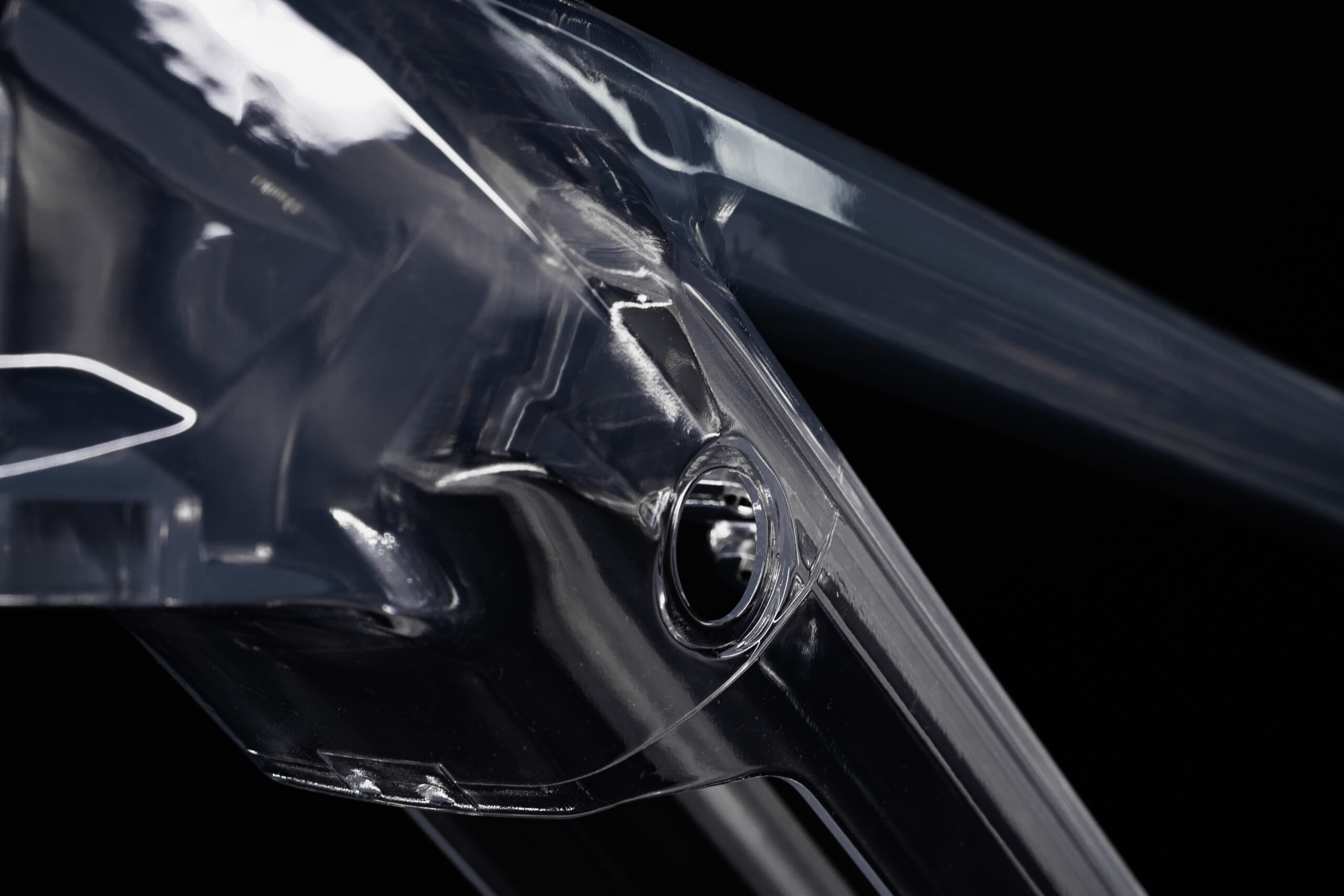

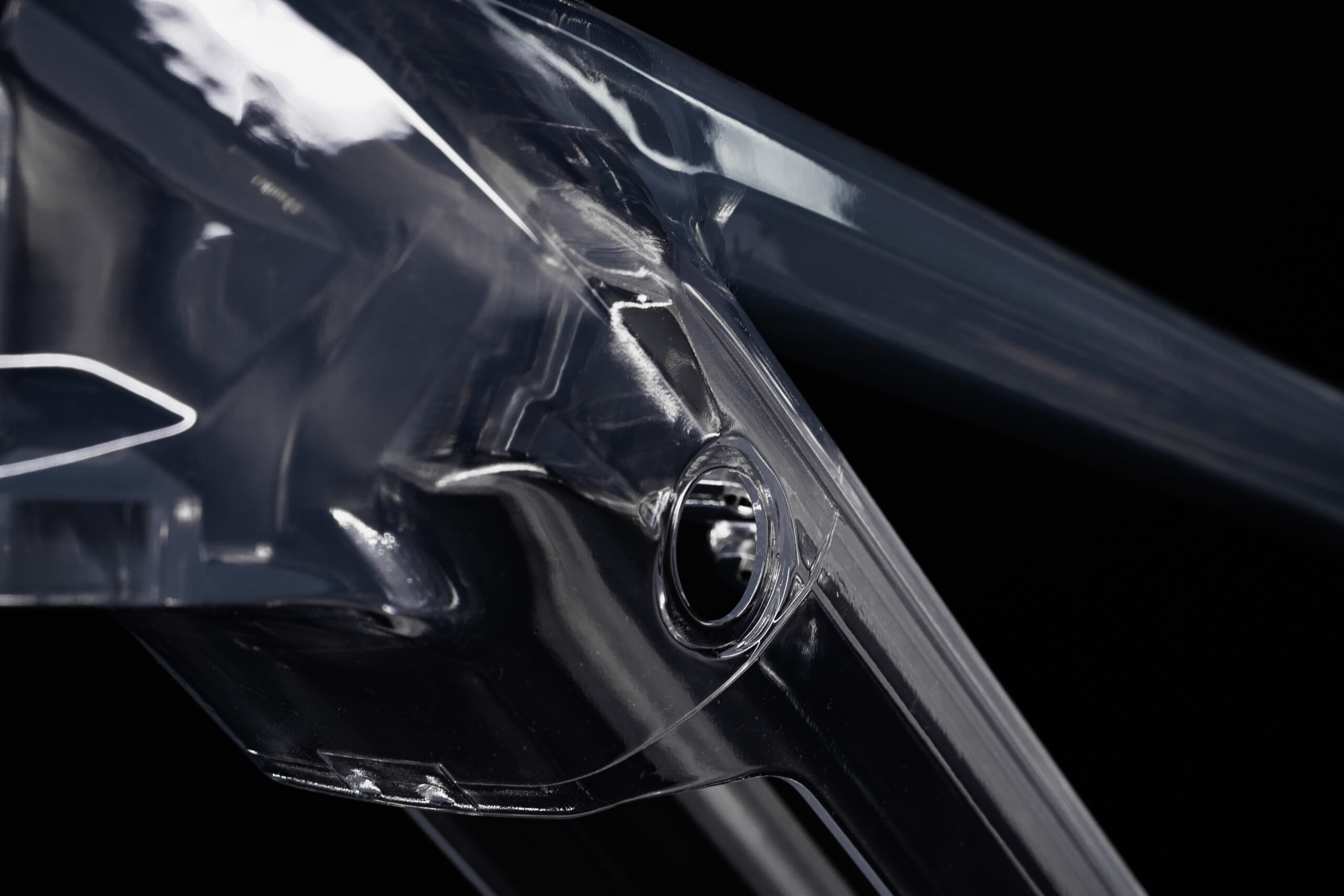

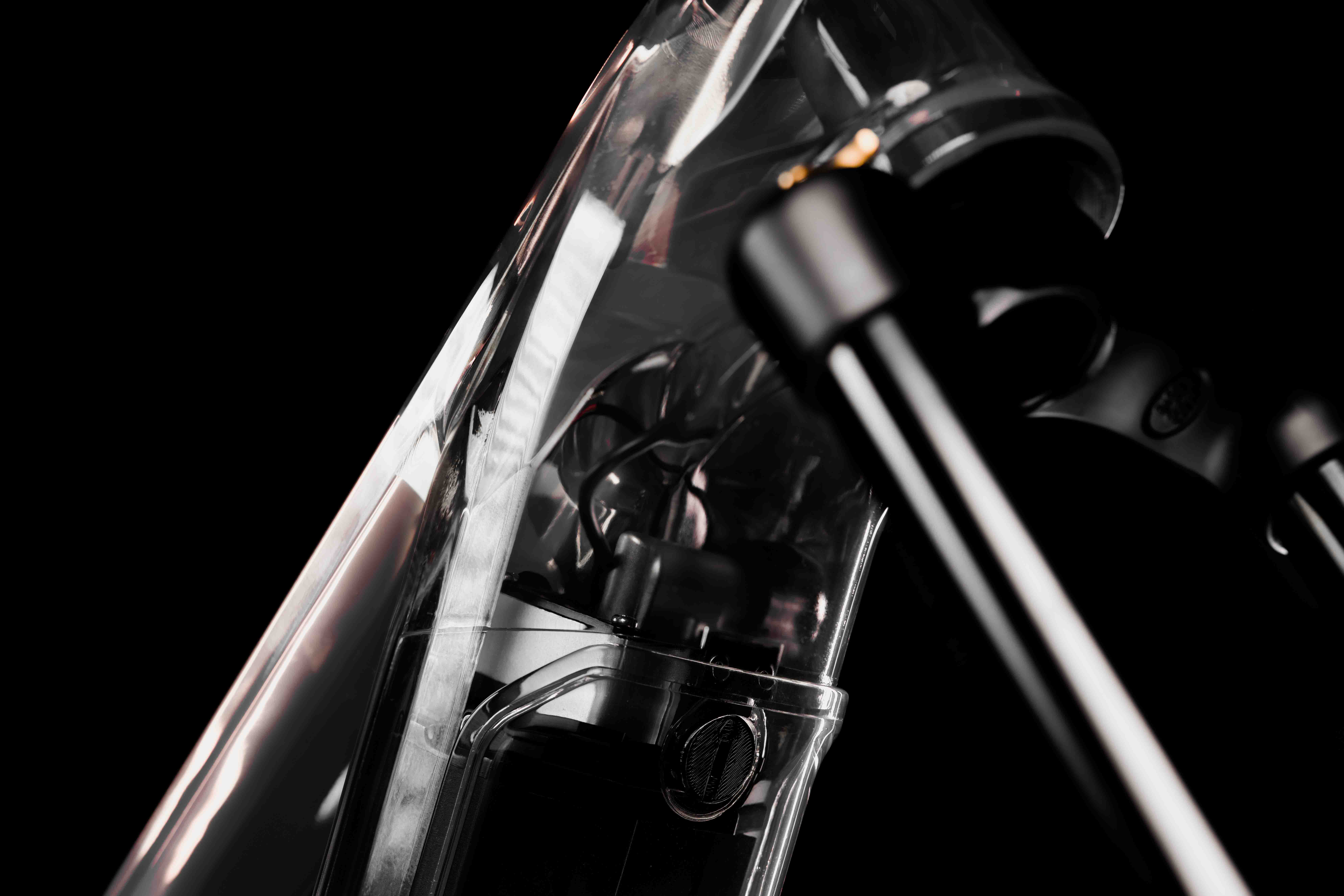

Les avantages du procédé d’impression 3D en stéréolithographie sont nombreux. Cette technologie permet de créer des objets avec une grande précision et une grande résolution, avec des détails très fins et des surfaces lisses très facile à peindre.

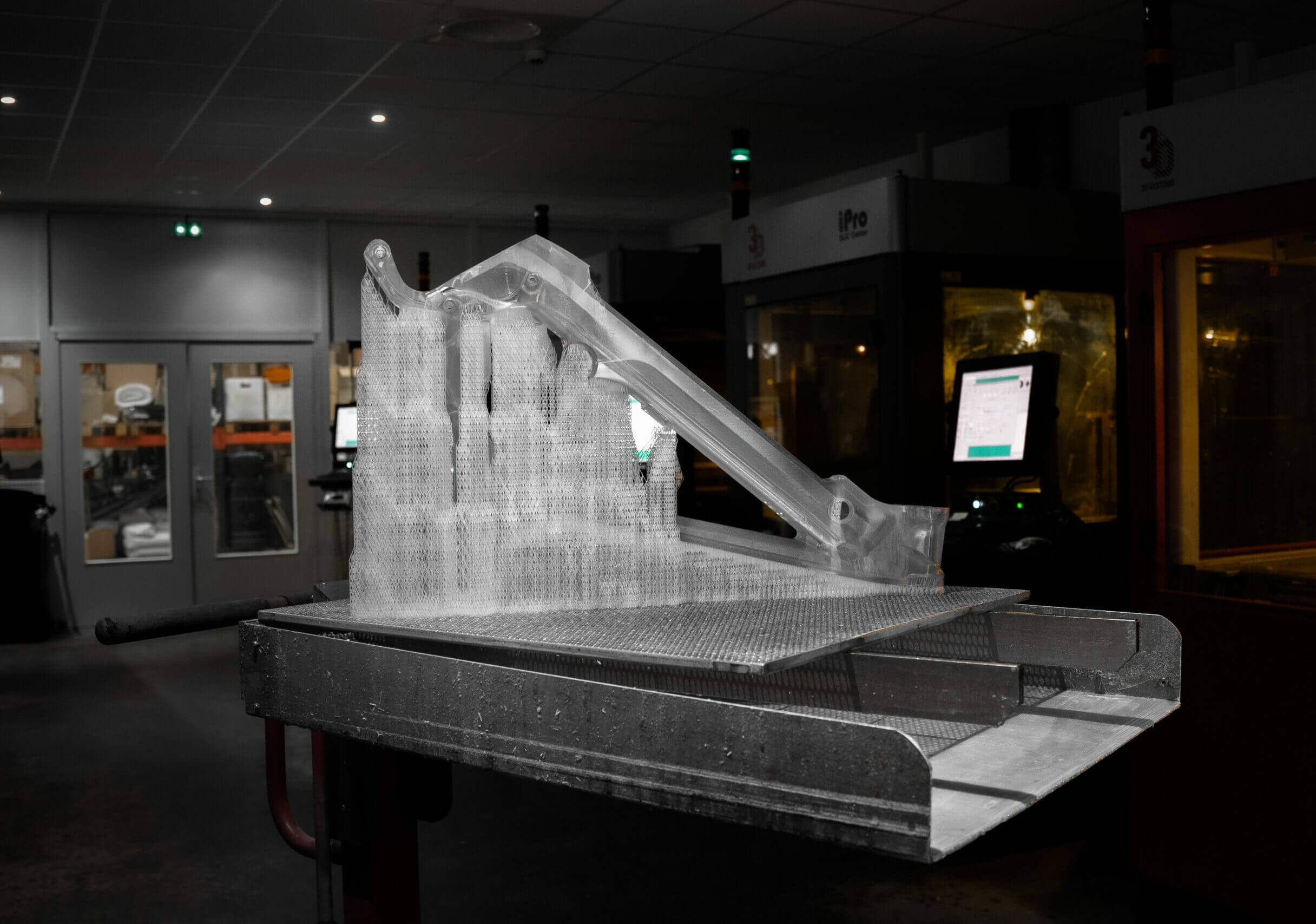

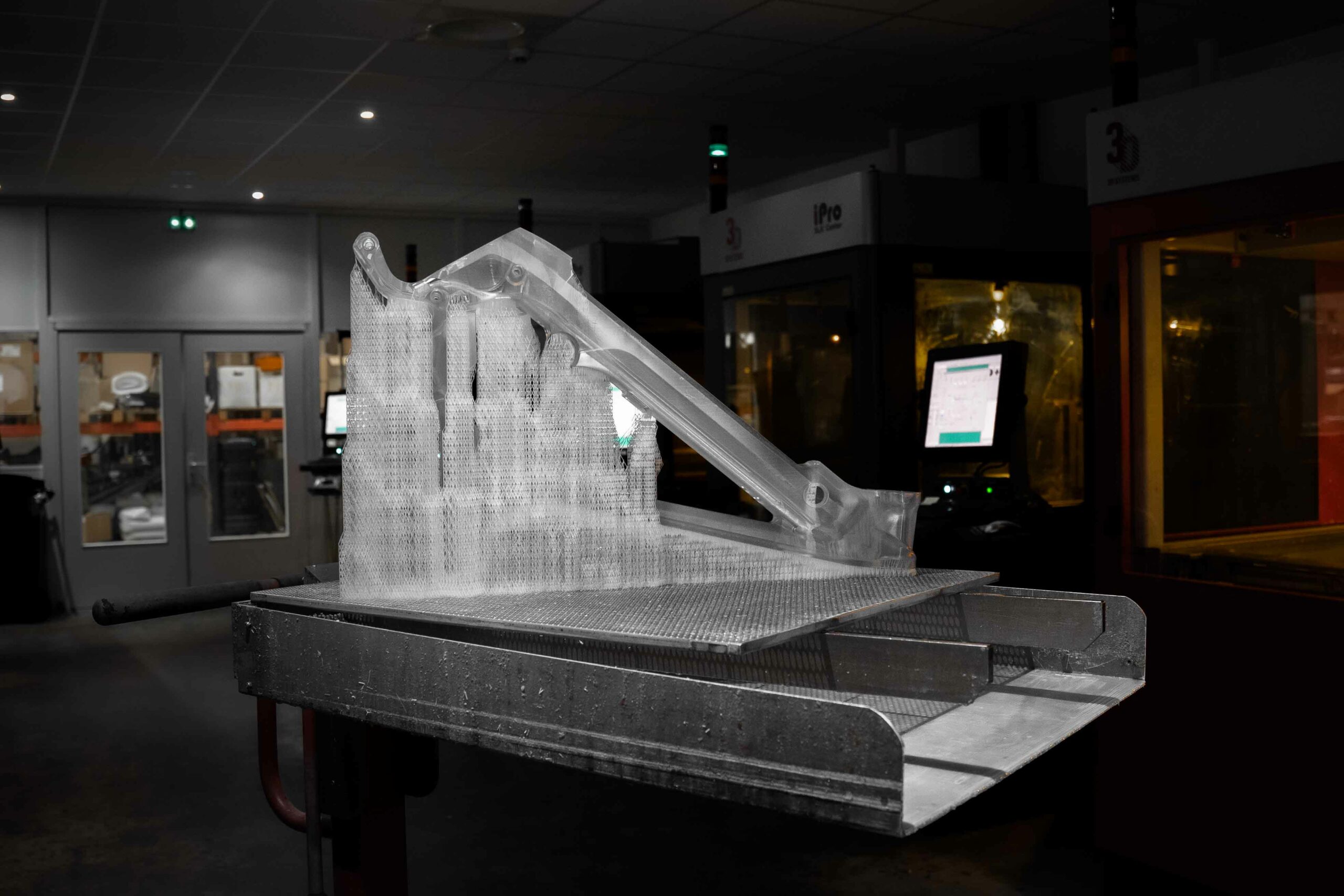

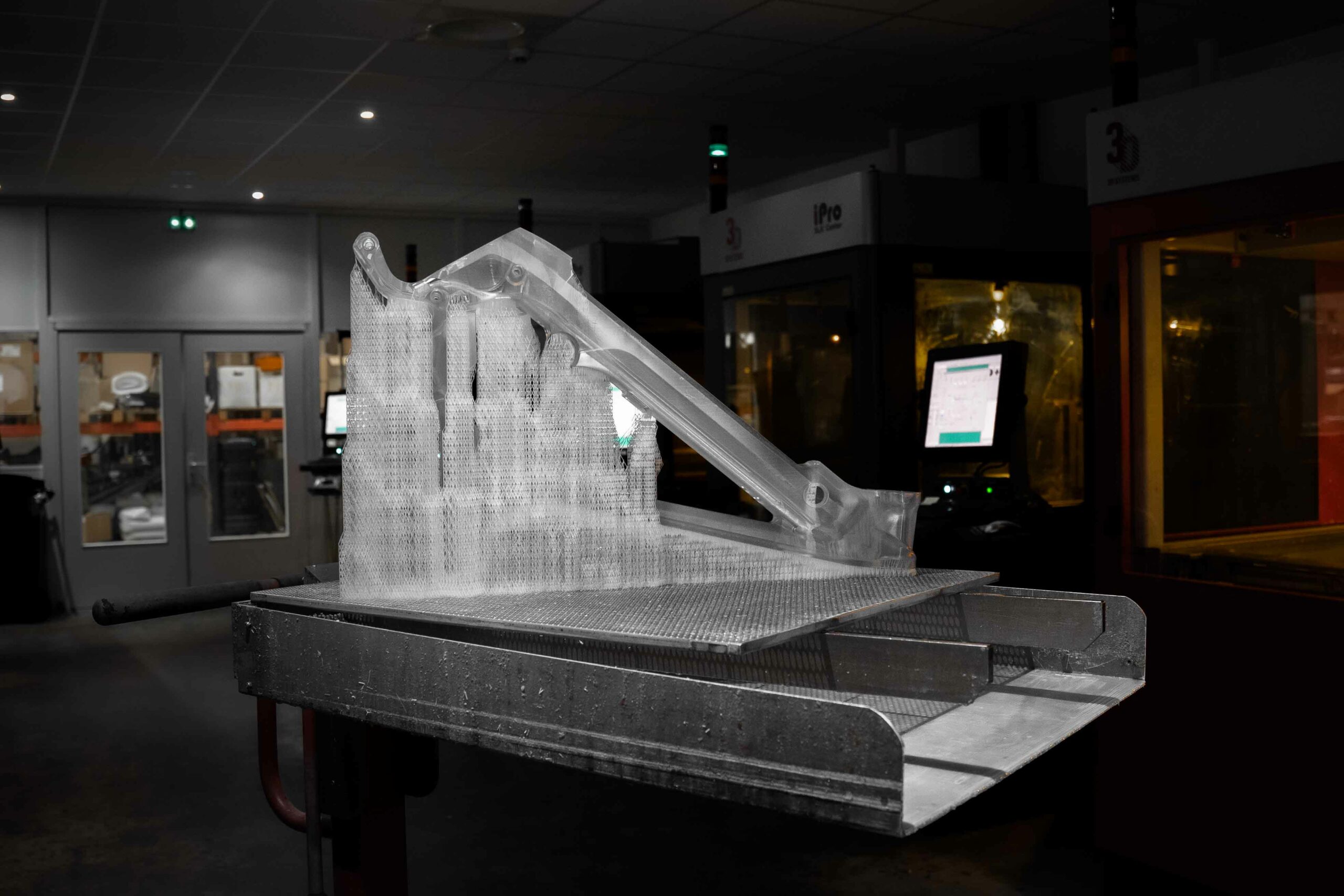

Principalement utilisé pour la création de pièces esthétiques de démonstration, elle offre la possibilité de créer des pièces complexes et monobloc (via l’utilisation de “supports” lors de l’impression) pouvant aller jusqu’à 2 mètres (calanque de voiture, tableau de bord, appareils électroménagers).

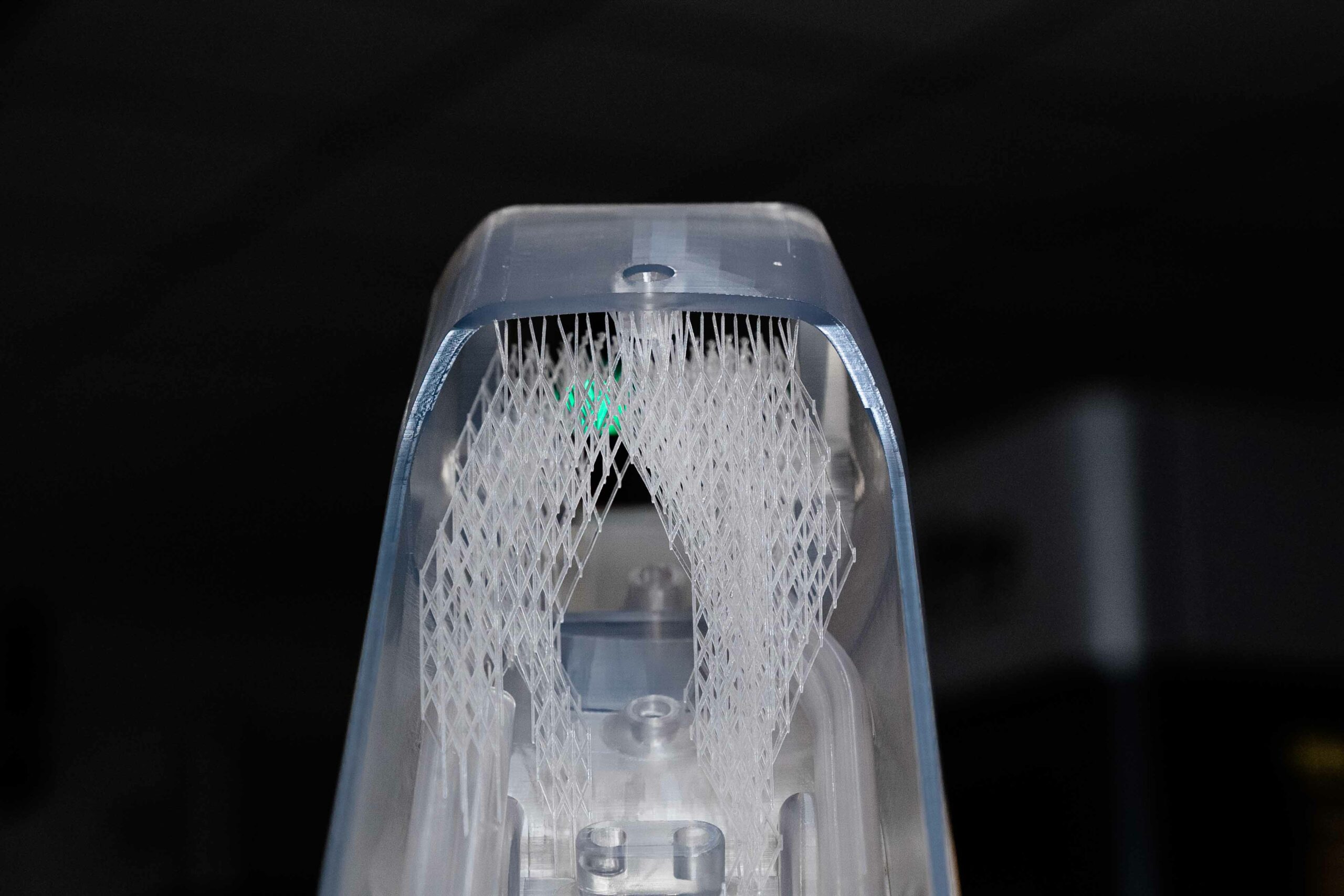

Ces structures de support sont nécessaires pour permettre l’impression de porte-à-faux, un travail de rinçage, de ponçage des supports et de durcissement post-impression est effectué à la main par nos équipes

Résine type ABS (SLA)

Résine type PP (SLA)

Résine type PA (SLA)

Résine type PC (SLA)

Votre devis en quelques minutes

Choisissez la technologie, le matériau, les finitions et obtenez votre devis instantanément grâce à notre plateforme en ligne.

1. Importez votre fichier CAO

Téléchargez votre fichier 3D (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf ou .zip (avec modèles et textures) fichier n’excédant pas 100 Mb

2. Choisissez la technologie 3D et les matériaux

Choisissez la technologie, le matériaux et les finitions et commandez en ligne.

Nos experts sont à votre disposition pour tous vos projets 3D

FAQ sur la Stéréolithographie

Contactez-nous dès maintenant pour discuter de votre projet !

Notre équipe vous recontactera pour concrétiser votre projet !