Ces derniers mois ont été intenses ! Nous avons procédé à de nombreuses évolutions dans nos ateliers qui nous permettent d’améliorer nos délais et la qualité de nos produits. Voyez plutôt !

Coulée sous vide : encore plus de possibilités

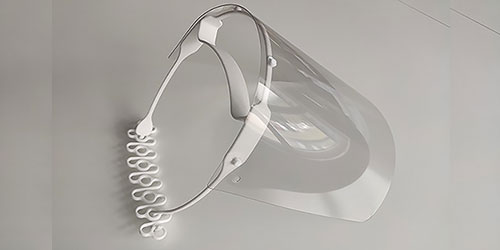

Vous êtes de plus en plus nombreux à avoir identifié les possibilités de la coulée sous vide dans votre activité, c’est pourquoi il était nécessaire de nous doter d’une nouvelle machine, mais pas n’importe laquelle! Nous sommes aujourd’hui capables de réaliser grâce à notre nouvelle acquisition des pièces allant jusqu’à 5 kg dans un moule pouvant mesurer jusqu’à 550 x 800 x 600 mm.

Cette machine nous permet donc de réaliser des pièces plus importantes, plus grandes et plus lourdes que ce qu’il était possible de faire jusque-là.

Bien entendu, comme cela était déjà le cas, ces pièces peuvent être teintées dans la masse avec des pigments ou des colorants directement mélangés dans la résine, pour un rendu encore meilleur!

La coulée sous vide est une technologique très spécifique !

Nous contacter pour une étude de faisabilité

Des finitions peinture qui vous surprendront

Peindre dans des conditions optimales, semblables à celles des fabricants de voitures ou de maquettes, voilà notre objectif pour un rendu toujours plus proche de la réalité. C’est la raison pour laquelle nous avons investi dans une cabine de peinture qui nous permet non seulement d’améliorer la qualité de nos finitions peintures et vernis grâce à son environnement professionnel, mais aussi de vous proposer de nouvelles peintures. Une amélioration de la qualité mais aussi de la performance grâce au système d’étuve qui nous fait gagner du temps sur le séchage et permet donc de raccourcir les délais de finitions.

Une collaboration fructueuse pour une qualité impeccable

Alors que le nettoyage des supports de pièces réalisées en stéréolithographie se fait traditionnellement à la main, nous avons développé une machine de nettoyage en collaboration avec Krumm. Créée sur-mesure, elle est parfaitement adaptée à nos besoins et nous permet de nettoyer en une fois nos grille d’1,50 m. Ce sont donc quelques centaines de pièces qui peuvent être prêtes en quelques minutes. Une amélioration dans les temps de production mais aussi dans la qualité des objets finis.

En savoir plus sur la coulée sous vide