The advantages of MJF 3D printing with 3DPROD

Accuracy

Speed

Resistance

What is Multi Jet Fusion MJF?

Multijet Fusion technology is an industrial 3D printing method developed by HP. It uses a powder fusion process to create parts using a variety of thermoplastic materials.

It works by depositing thermoplastic powder on a build plate, then using a print head to spray a fusing agent and detailing agent onto the powder layer. The powder is then heated to selectively melt the areas corresponding to the first slice of the model.

This process is repeated layer by layer until the object is fully formed.

The benefits of Multi Jet Fusion

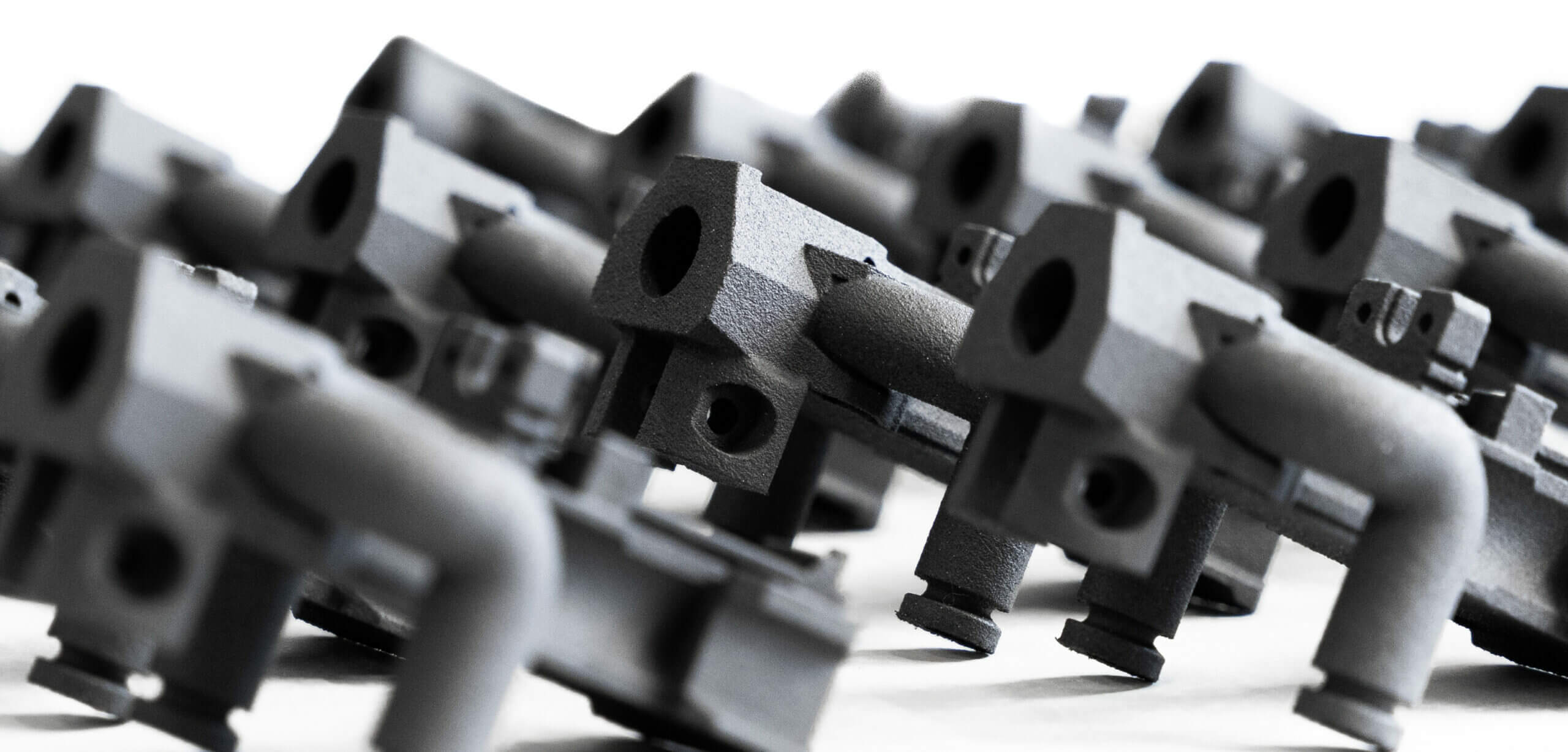

Multijet Fusion technology offers advantages such as fast printing speeds, high precision, high surface quality, and high mechanical resistance of the parts produced.

PA thermoplastics offer good chemical resistance chemical resistance and low moisture absorption. The raw material is gray in color and may be mottled at times. Parts made with Multijet Fusion are naturally watertight, thanks to the use of fusing agents and details.

The main difference between powder sintering and Multijet Fusion lies in its greater aesthetic precision (with similar technical constraints).

PA powder (MJF)

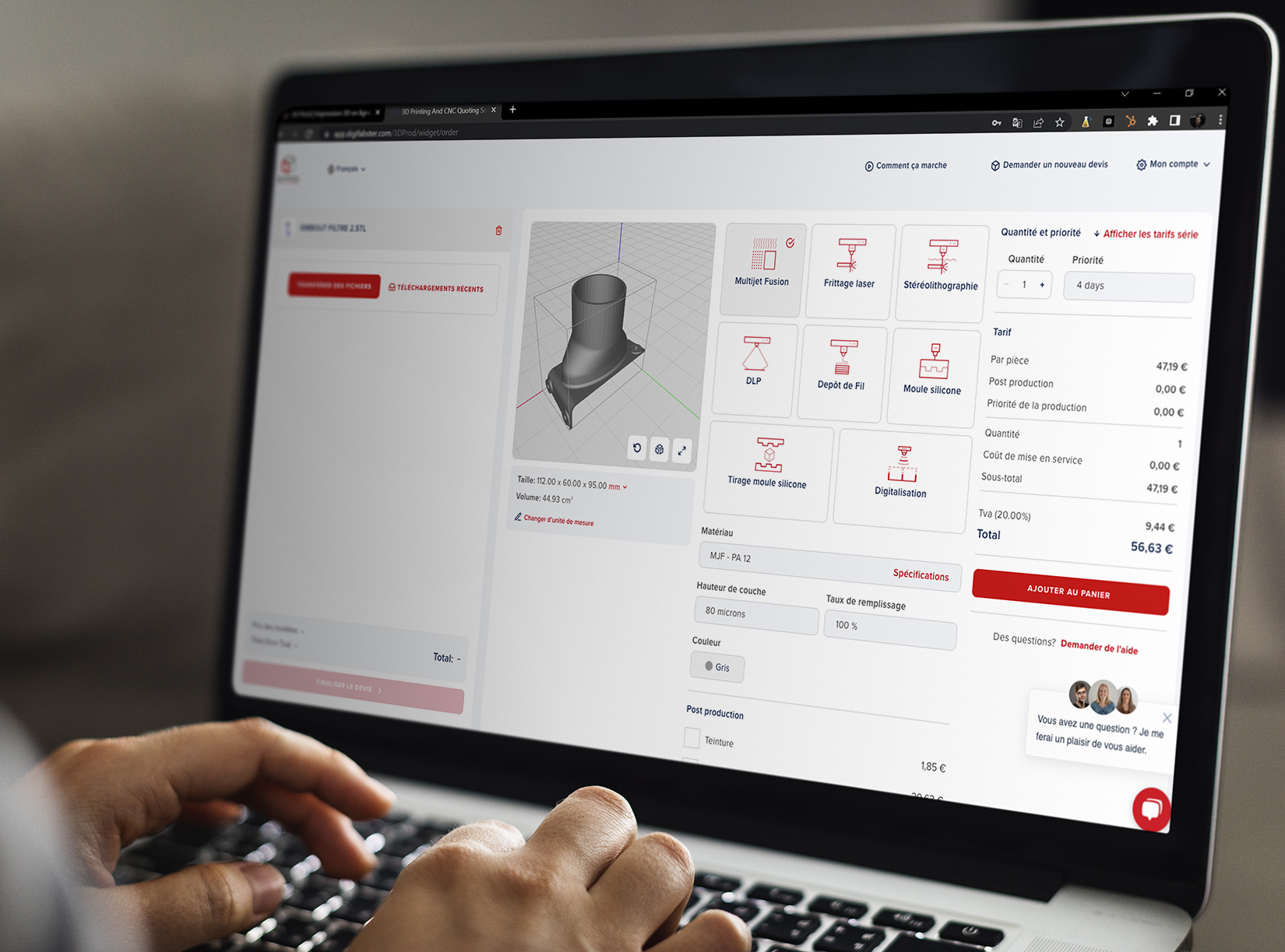

Your quote in minutes

Choose the technology, the material, the finish and get your quote instantly via our online platform.

1. Import your CAD file

Upload your 3D file (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf or .zip (with models and textures) file not exceeding 100 Mb

2. Choose 3D technology and materials

Choose technology, materials and finishes and order your project online.

Our experts are at your disposal for all your 3D projects

Multi Jet fusion FAQs

Contact us today to discuss your project!

Our team will get back to you to make your project a reality!