FL Création accelerates new product development thanks to 3D Prod's expertise

FL Création is a French company based in the Oise region, which chose 3D Prod as its partner 4 years ago. Creator of glasss for 20 years, the company has relied on HP Multi Jet Fusion technology to design certain parts of its kit glass roofs, sold under the Kit Atelier brand. It chose additive manufacturing to accelerate product development and control costs. Thanks to the teams at 3D Prod, it can count on quality parts, delivered quickly and easily from our online store.

Founded 20 years ago, FL Création manufactures steel and aluminum skylights. A few years ago, the company turned to 3D printing to produce prototypes. She invested in a desktop machine and began making a few parts. Very quickly, she decided to work with a supplier to ensure the quality and aesthetics of the parts. Their objective was to be able to count on a printing service that was reactive, competitive in terms of price and attentive to their needs. After studying the market, FL Création, and more specifically its Kit Atelier brand, chose 3D Prod to produce these parts.

Accelerate new product development with additive manufacturing

It all began with the development of new hinged doors that included frame covers and feet. The idea was to have a symmetrical frame so that you could choose the direction in which the door opened during assembly. As these parts are visible, they had to be at least aesthetically pleasing, with an attractive surface finish. Guillaume Dumesnil works in the FL Création design office.

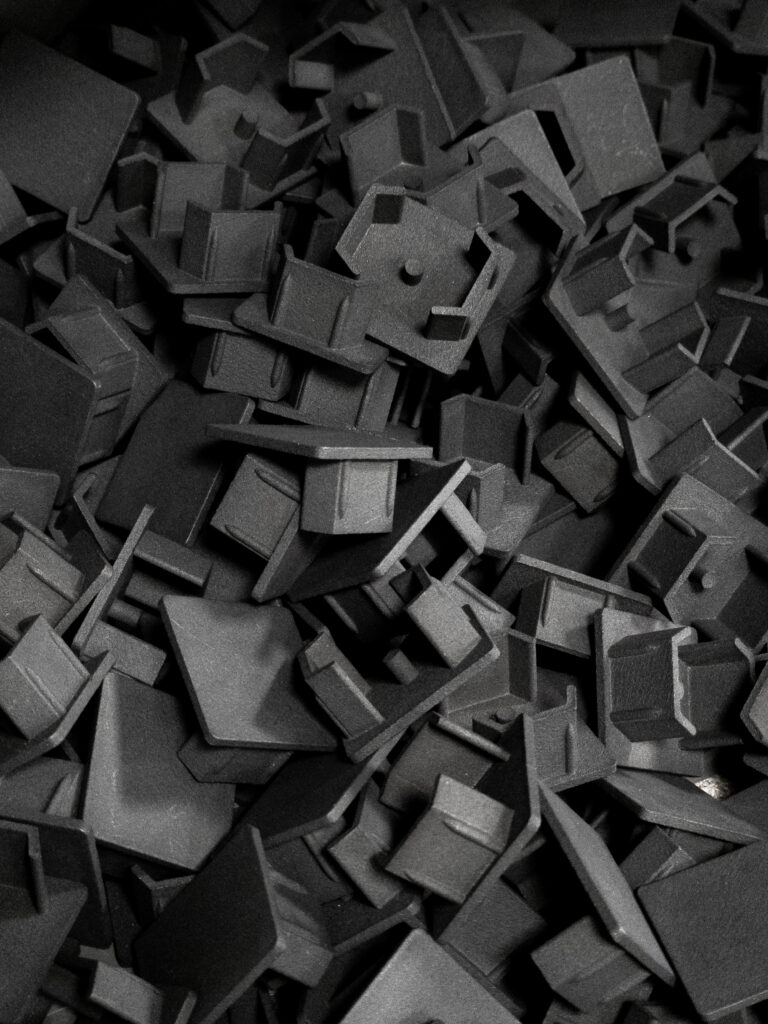

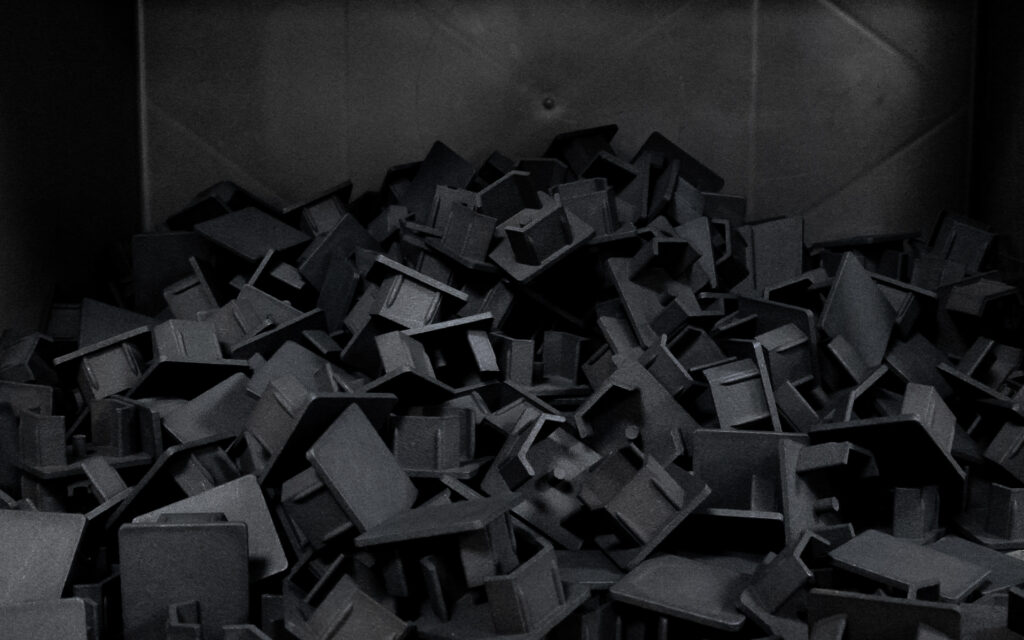

He explains: "We needed parts in medium production runs. These are mainly door covers and feet for our structures. They are not subject to any particular mechanical constraints, so we needed aesthetic parts that could be produced quickly despite their limited number.."

As the number of parts to be produced was relatively small at the outset, it didn't justify the creation of an expensive and time-consuming mold. The company therefore turned to additive manufacturing, and more specifically to a specialist, to achieve satisfactory results.

FL Création's choice of Multi Jet Fusion technology

It wasn't long before 3D Prod's teams came up with Multi Jet Fusion technology and PA 12, a process that enables medium-sized production runs to be produced easily and in record time, thanks to the use of agents that control powder fusion. It's an ideal technology for high productivity. It also offers a smooth surface finish, with the possibility of quick and easy post-processing. 3D printed parts can be tinted, for example. Our teams can provide this finishing service to suit your needs, using professional, high-quality equipment.

Our teams held several preparatory meetings with FL Création to understand their products and needs. We also helped them understand 3D printing technologies by training them in the fundamentals of additive manufacturing. By opting for the Multi Jet Fusion process, we are able to produce the required quantities of parts in record time. On average, the French company orders between 300 and 500 parts per batch, which we are able to deliver in 15 days. We have therefore produced thousands of parts since the start of our collaboration.

Guillaume continues: "We're very satisfied with 3D Prod's support and responsiveness. The teams are always ready to listen, and we have quality contacts. What's more, we can take advantage of local manufacturing, as Made in France is always a plus for the end customer.."

For FL Création, additive manufacturing not only helps them control costs when launching a new product, but also enables them to obtain parts more quickly. Teams no longer have to wait for a mold to be produced, and can easily validate their concepts.

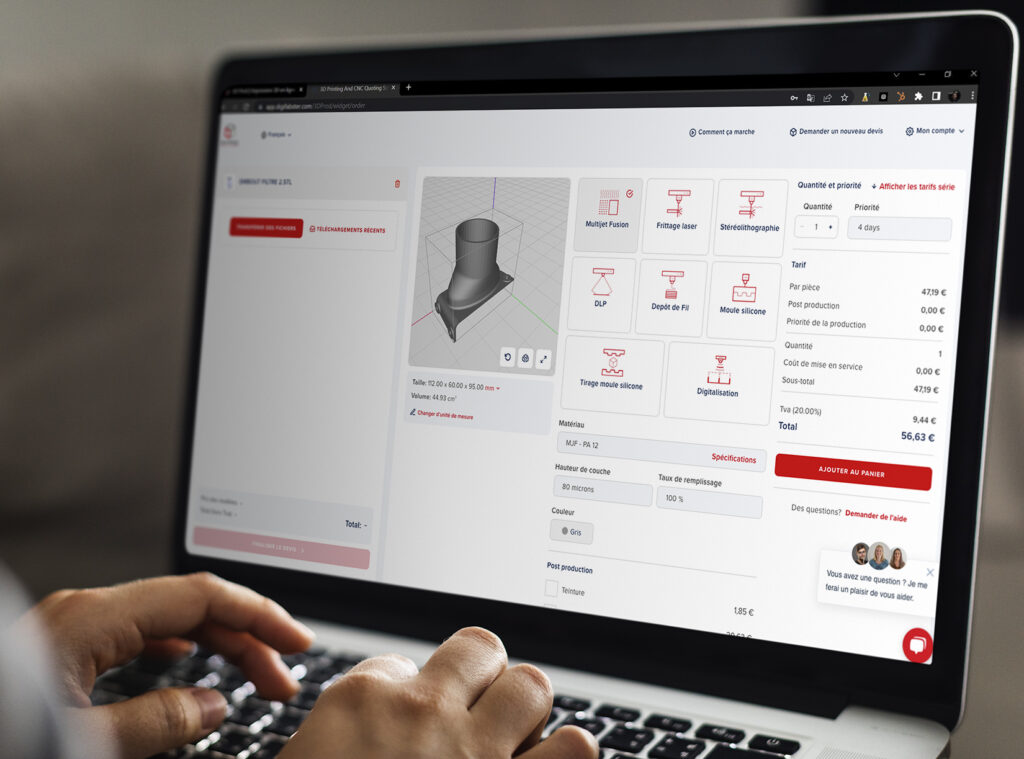

An accessible online store

Most of FL Création's parts are ordered via our online store: all they have to do is upload their 3D file, choose the Multi Jet Fusion technology, the PA12 powder and the appropriate post-processing in just a few clicks. The process is fast, accessible and easy to use.

Guillaume adds: "We can place orders directly and autonomously, which is a very important criterion. If we ever encounter any difficulties, we can also call the 3D Prod teams, who are able to solve our problem very quickly.."

Our online store enables you to order prototypes, models and small series quickly. Simply upload your 3D file and choose the additive manufacturing technology and material you require. Every order includes support from our team, who receive ongoing training in 3D printing technologies and the challenges posed by each of them. It's a professional service that will enable you to obtain your parts quickly and efficiently.

Guillaume from FL Création concludes: "I highly recommend 3D Prod's services. Their team is made up of professionals who understand our needs and constraints, and know how to propose the right solution. Production and delivery times are short, without sacrificing quality.."

Do you have a manufacturing project? Contact our teams today to receive tailor-made support and benefit from the advantages of additive manufacturing!

3D Prod tip : Test your projects by making your quotes online via our dedicated platform: Get your quote online!