Les avantages de la coulée sous vide avec 3DPROD

Résine variée

Précision

Résistance mécanique

Qu’est ce que la Coulée sous vide ?

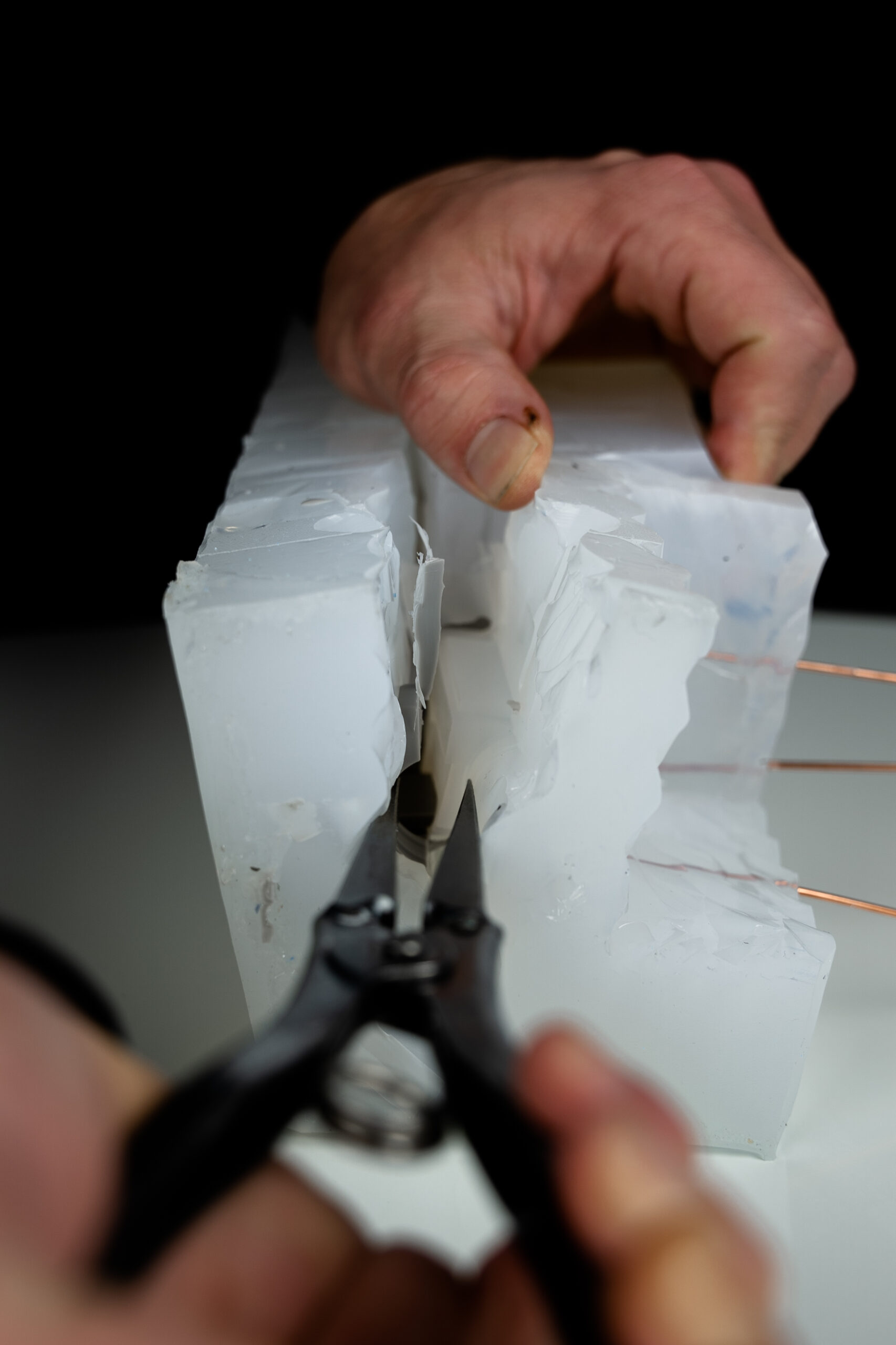

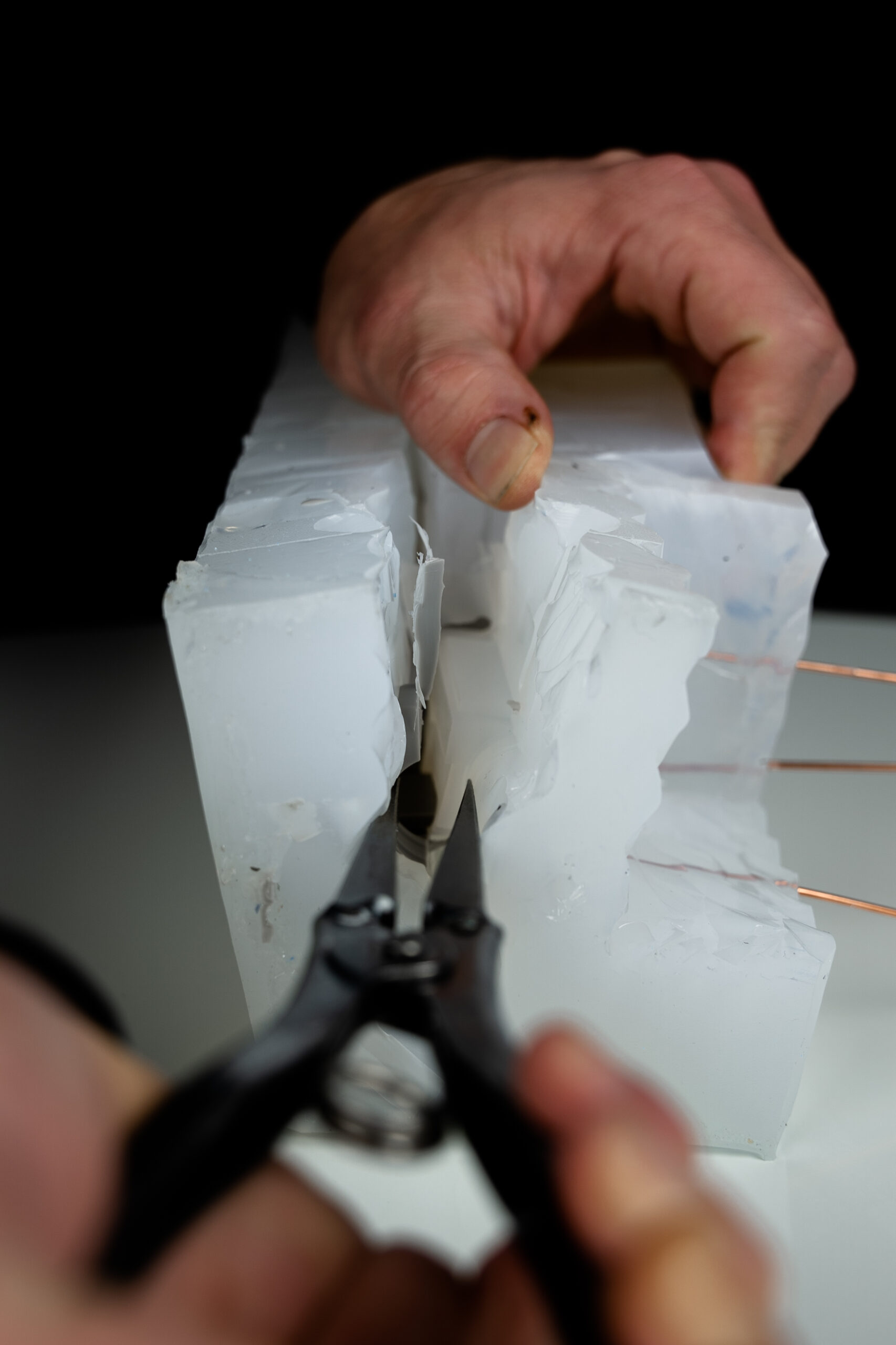

La technique de coulée sous vide constitue une méthode inégalée pour reproduire fidèlement une pièce, tirant profit d’un moule en silicone créé à partir d’un modèle généralement réalisé en Stéréolithographie. Une fois le moule confectionné, une résine en polyuréthane est versée, adoptant naturellement la forme de l’empreinte.

Cette approche offre une diversité remarquable en termes de matériaux, de niveaux de dureté et de couleurs. Elle permet ainsi la réalisation de prototypes parfaitement conformes au modèle original, garantissant une qualité exceptionnelle. La coulée sous vide émerge comme une solution économique, particulièrement adaptée à la production de petites séries, de prototypes et de pré-séries sans passer par de l’injection plastique.

Les avantages de la Coulée sous vide

La coulée sous vide est utilisée pour produire des pièces en petite et moyenne série (jusqu’à 25 tirage maximum par moule) avec une grande précision de détails et une finition de surface élevée.

Cette technologie peut être une alternative plus économique que la plasturgie pour la production de petites séries industrielles, car elle nécessite moins d’investissements en équipement et en outillage (la plasturgie nécessitant des moules spécifiques, long à réaliser). De plus, la coulée sous vide offre la possibilité de modifier les couleurs et les matériaux lors des différents tirages (utile pour du A/B testing).

N’hésitez pas à contacter nos experts, nous pouvons vous accompagner sur les points de ruptures entre l’injection et l’impression 3D.

Vaste choix de résine

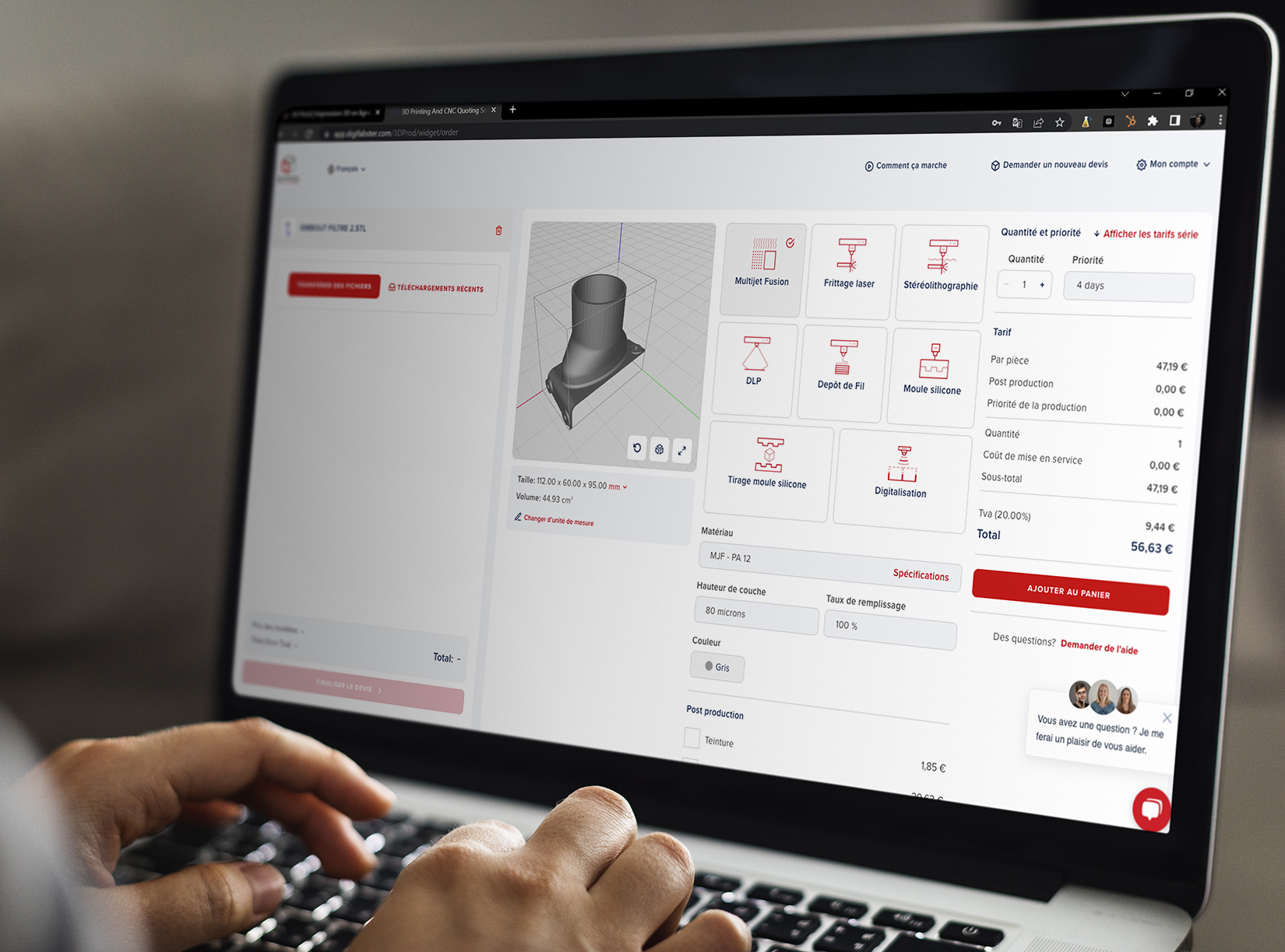

Votre devis en quelques minutes

Choisissez la technologie, le matériau, les finitions et obtenez votre devis instantanément grâce à notre plateforme en ligne.

1. Importez votre fichier CAO

Téléchargez votre fichier 3D (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf ou .zip (avec modèles et textures) fichier n’excédant pas 100 Mb

2. Choisissez la technologie 3D et les matériaux

Choisissez le matériau idéal parmi nos résines pour coulée sous vide et vos finitions et commandez en ligne.

Nos experts sont à votre disposition pour tous vos projets 3D

FAQ sur la coulée sous vide

Contactez-nous dès maintenant pour discuter de votre projet !

Notre équipe vous recontactera pour concrétiser votre projet !