The benefits of DLP with 3DPROD

Ultra precision

Speed

Small series

What is Digital Light Processing ?

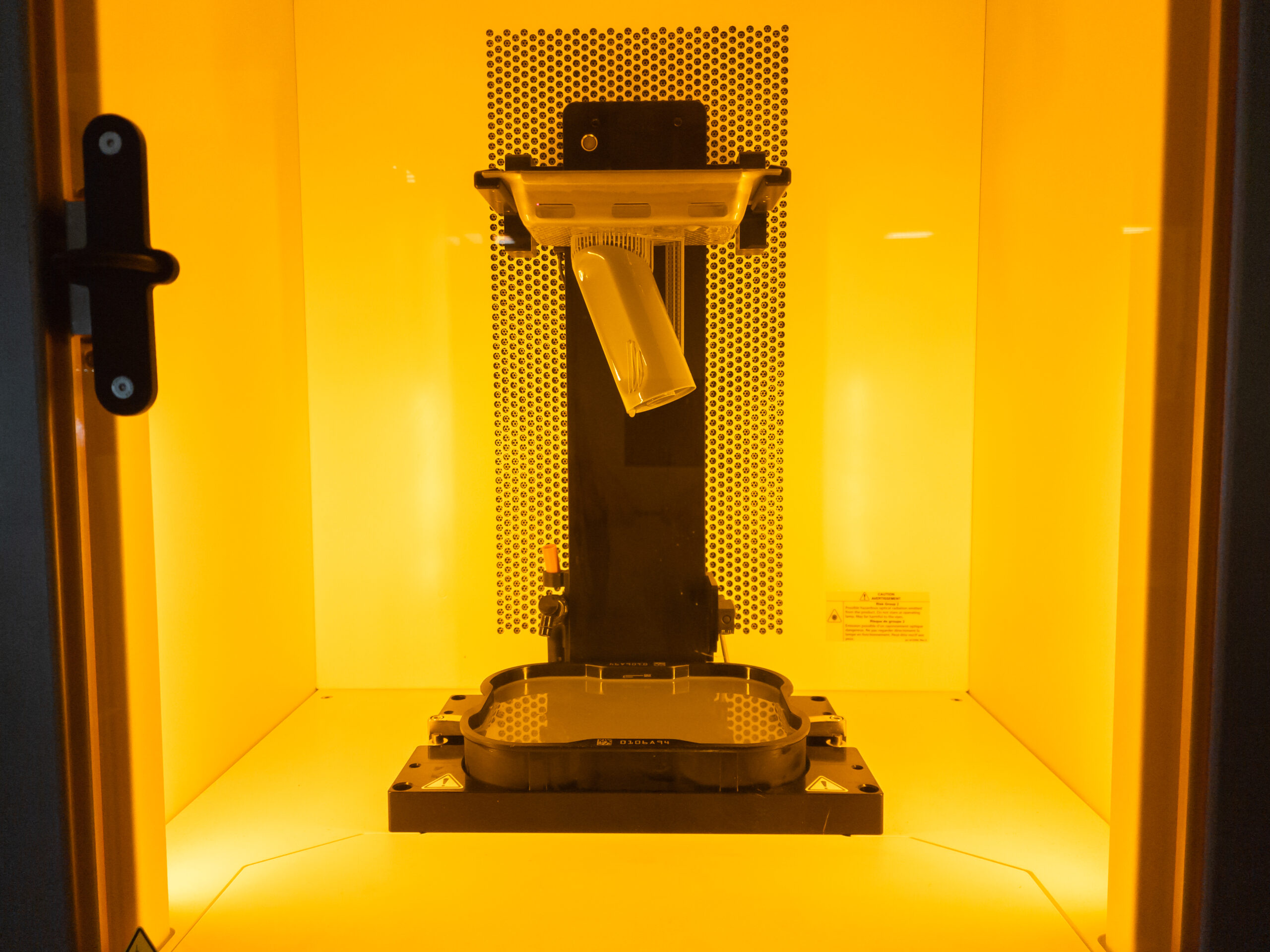

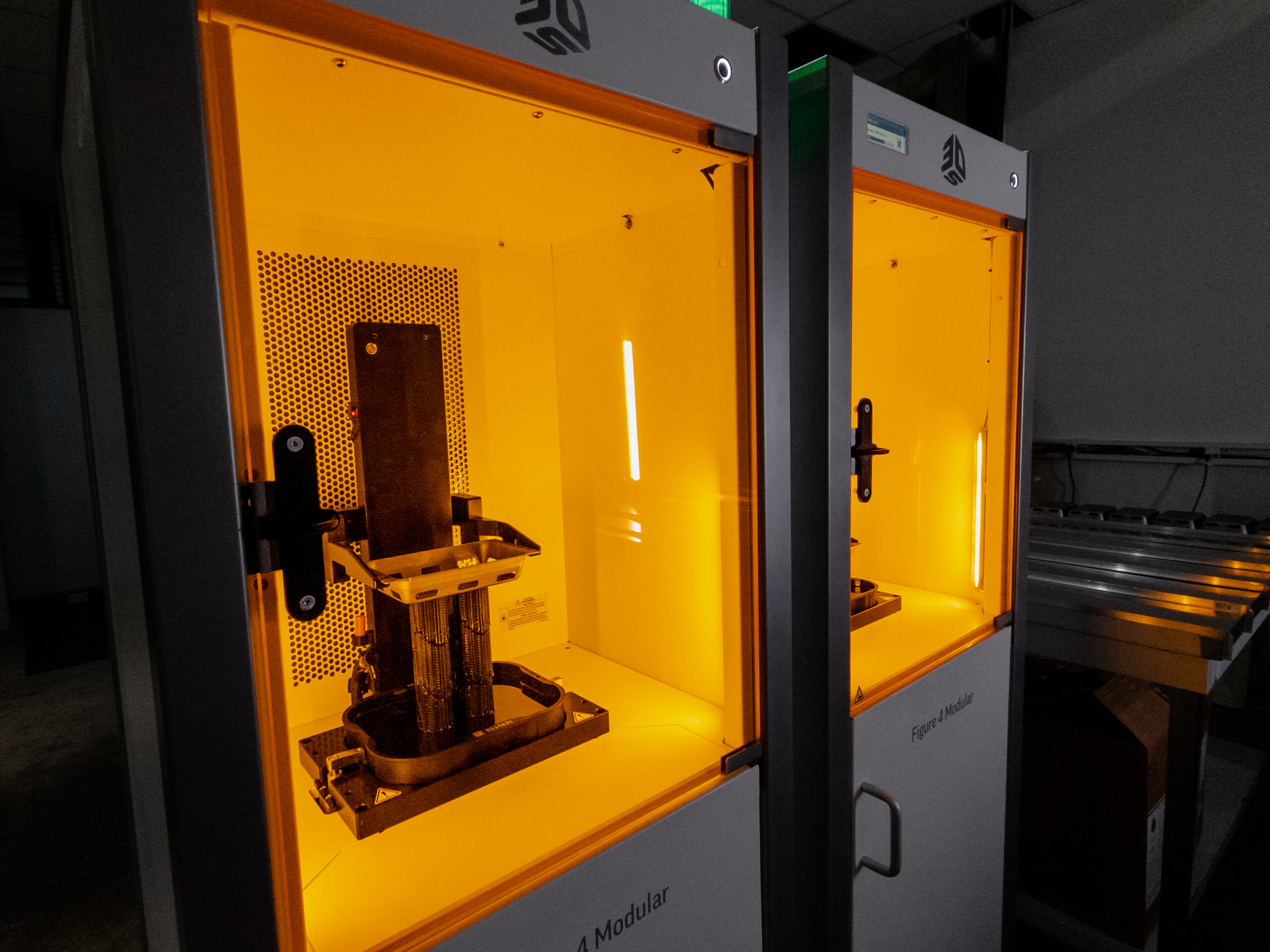

An ultra-fast, scalable, semi-automated additive manufacturing solution to meet the most demanding industrial needs.

Adapted to a variety of industrial applications DLP technology is particularly well suited to the production of mass-produced final parts and master models.

DLP technology revolutionizes traditional manufacturing methods while offering extremely short production cycles. Inspired by SLA technology, DLP uses the photopolymerization of a liquid resin with UV light. The difference is that the UV light source is a projector instead of a laser. Thus the complete image of each layer is projected in one time allowing to pass quickly to the following layer.

The benefits of DLP

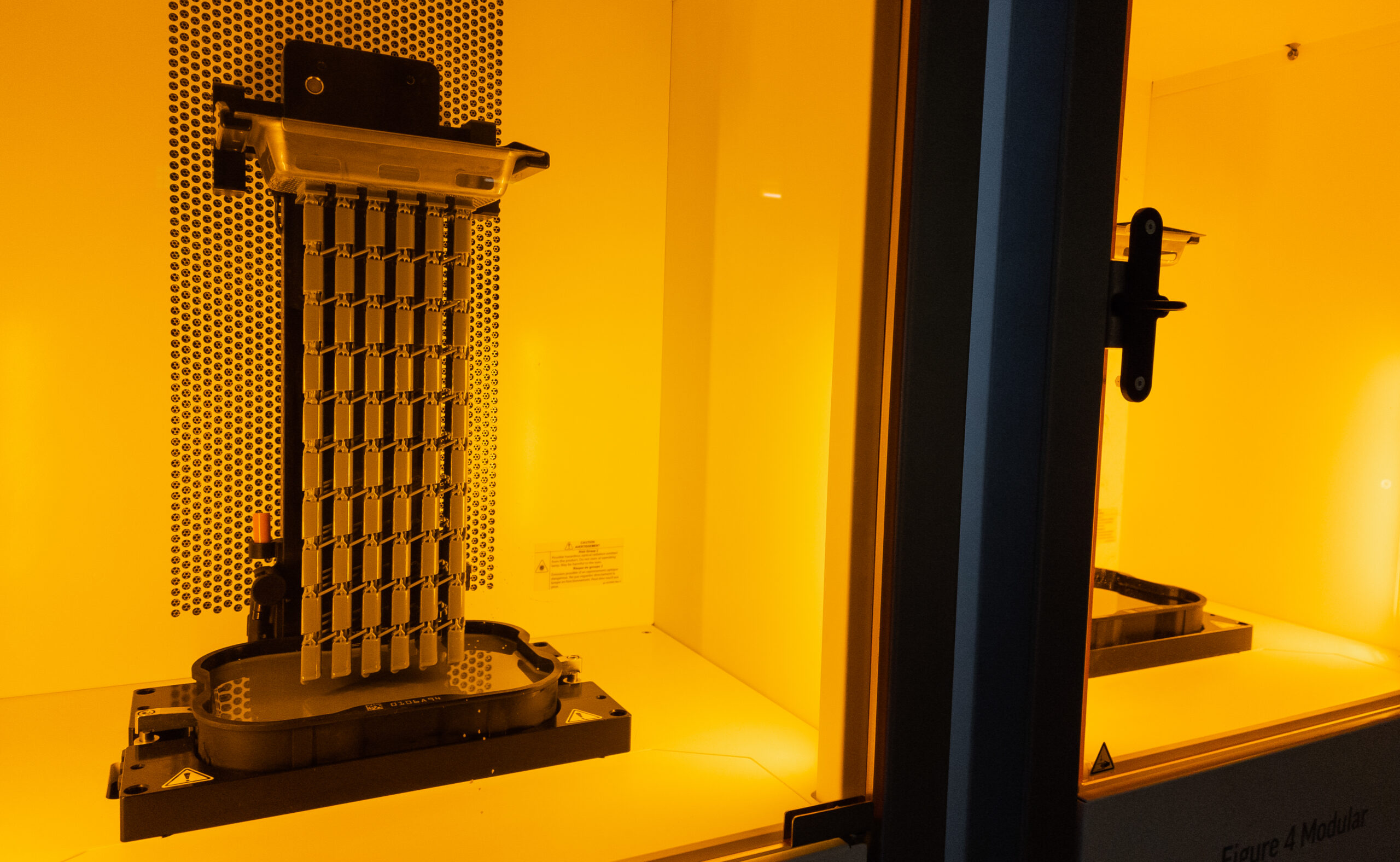

DLP technology delivers high-quality prints with fine detail and a smooth surface, and requires fewer print media than SLA, reducing the amount of material used and facilitating post-processing.

High-resolution models with a high level of detail, increased productivity and repeatability (Six Sigma), ideal for small and medium production runs at industrial level.

The Digital Light Processing (DLP) solution combines the efficiency and flexibility of 3D printing processes (manufacturing volume (xyz) 124 x 70 x 340 mm, minimum layer thickness of 0.01 mm and print speeds of up to 100 mm/h) with the performance of traditional injection molding processes.

Figure 4® PRO-BLK-10

Figure 4® RIGID GRAY

Figure 4® RUBBER-65A-BLK

Figure 4® HI TEMP 300-AMB

Figure 4® HI TEMP 150-AMB

Our experts are at your disposal for all your 3D projects

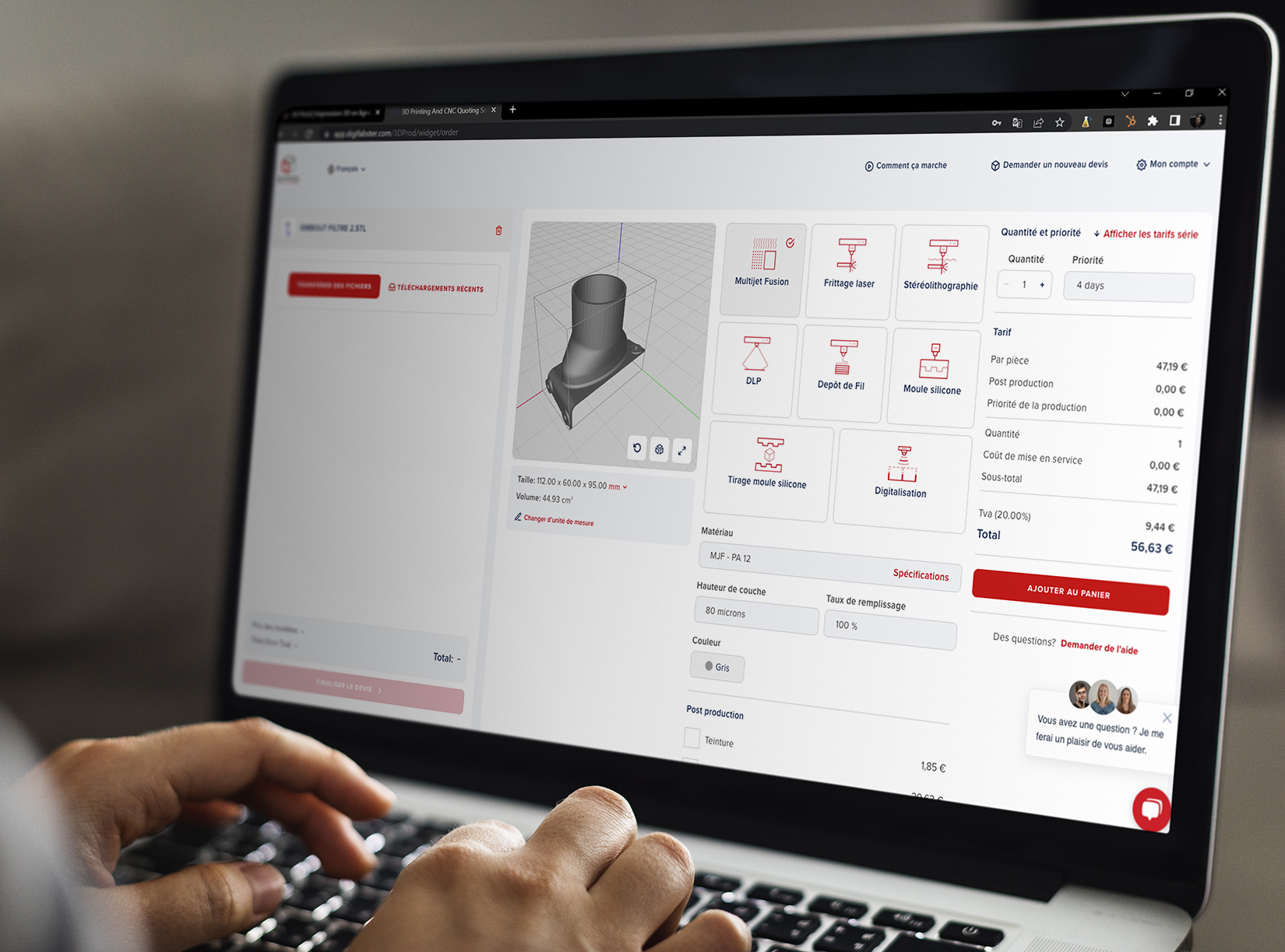

Your quote in minutes

Choose the technology, the material, the finish and get your quote instantly via our online platform.

1. Import your CAD file

Upload your 3D file (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf or .zip (with models and textures) file not exceeding 100 Mb

2. Choose 3D technology and materials

Choose your ideal DLP material, your finish and order online.