The 3D printing market is constantly evolving, with annual growth of around 20%, and is gradually making inroads into sectors as varied as textiles, industrial tools, music, art, jewelry, and decoration.

3D printing, a market in constant evolution

Thanks to the technical evolution of professional 3D printers, it is now the turn of the optical industry to take its first steps. The 3D printing technique opens new perspectives in the way of designing and producing frames.

3D printing in the optical industry

The subject of scientific research for several years, the trials of 3D printing of optical frames, until then not very successful, have finally borne fruit: making custom-made eyeglass frames for each customer, whatever the shape of his face, is now possible thanks to additive manufacturing.

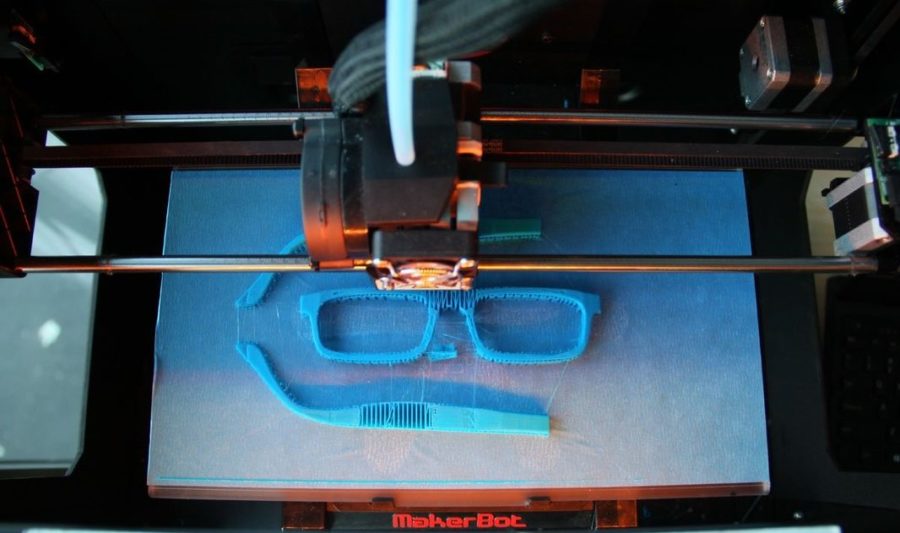

3D printing using the Makerbot Replicator 2 3D printer. Credits: Aaron Porterfield.

3D printing using the Makerbot Replicator 2 3D printer. Credits: Aaron Porterfield.

Several companies have already realized the potential of 3D printing in the optical industry, such as SODA Concept in Italy, Protos Eyewear in the United States, Hoya in Japan ( Yuniku) and Aoyama in France, all of which offer customized frames, adapted to the shape and characteristics of each individual face. After four years of research and development, it's Belgium's turn to innovate: in 2013, designer Patrick Hoet launches the first 3D printed titanium eyewear frames, the result of a long collaboration with the company Melotte. These ultra-lightweight stainless steel frames signed Hoet Couture were manufactured using the Selective Laser Sintering process on metal alloys. The 3D printed frames offered on the market are on average 20 to 30% lighter than conventional optical equipment.