Les avantages de l'impression 3D dépôt de fil avec 3DPROD

Prix

Rapidité

Résistance mécanique

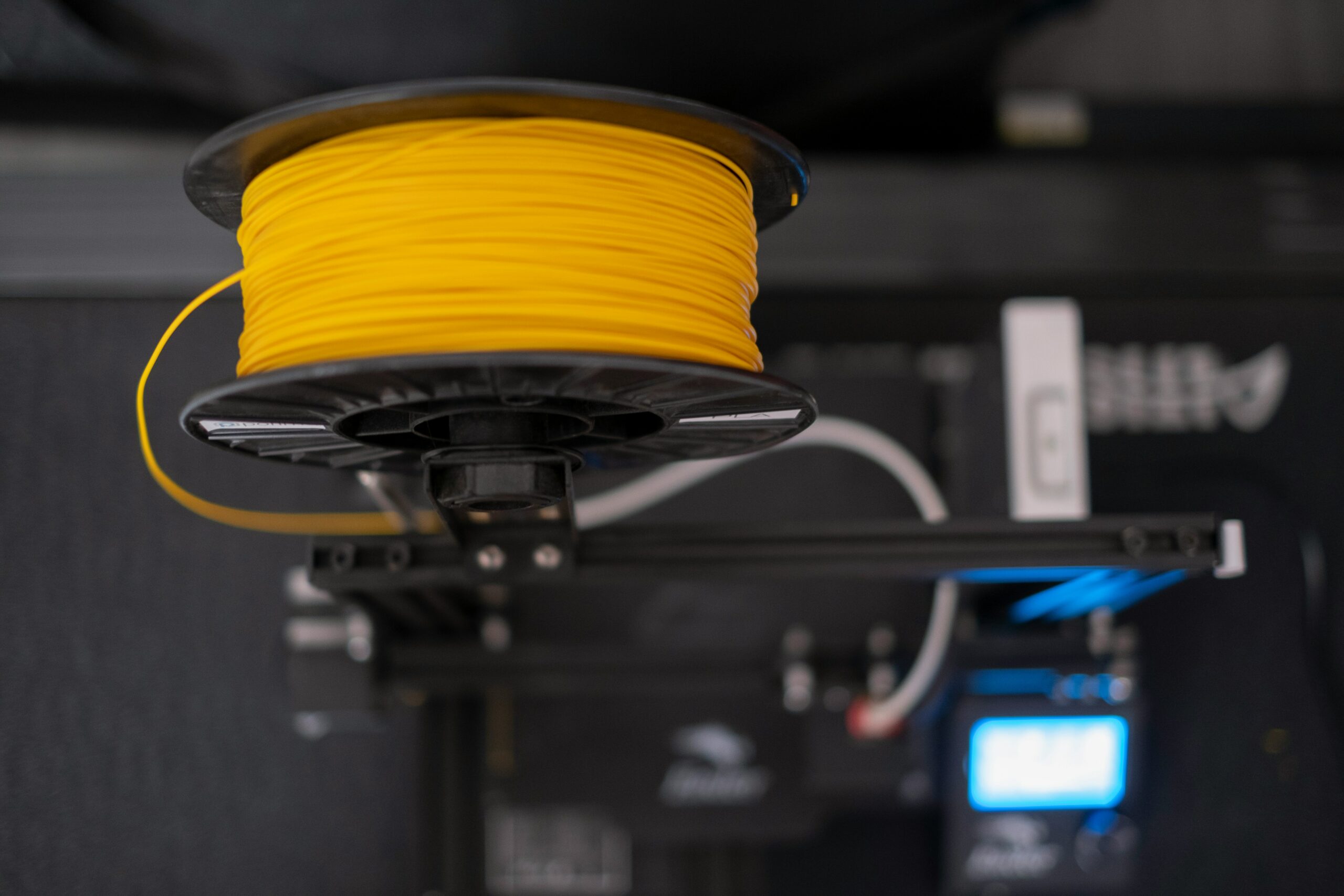

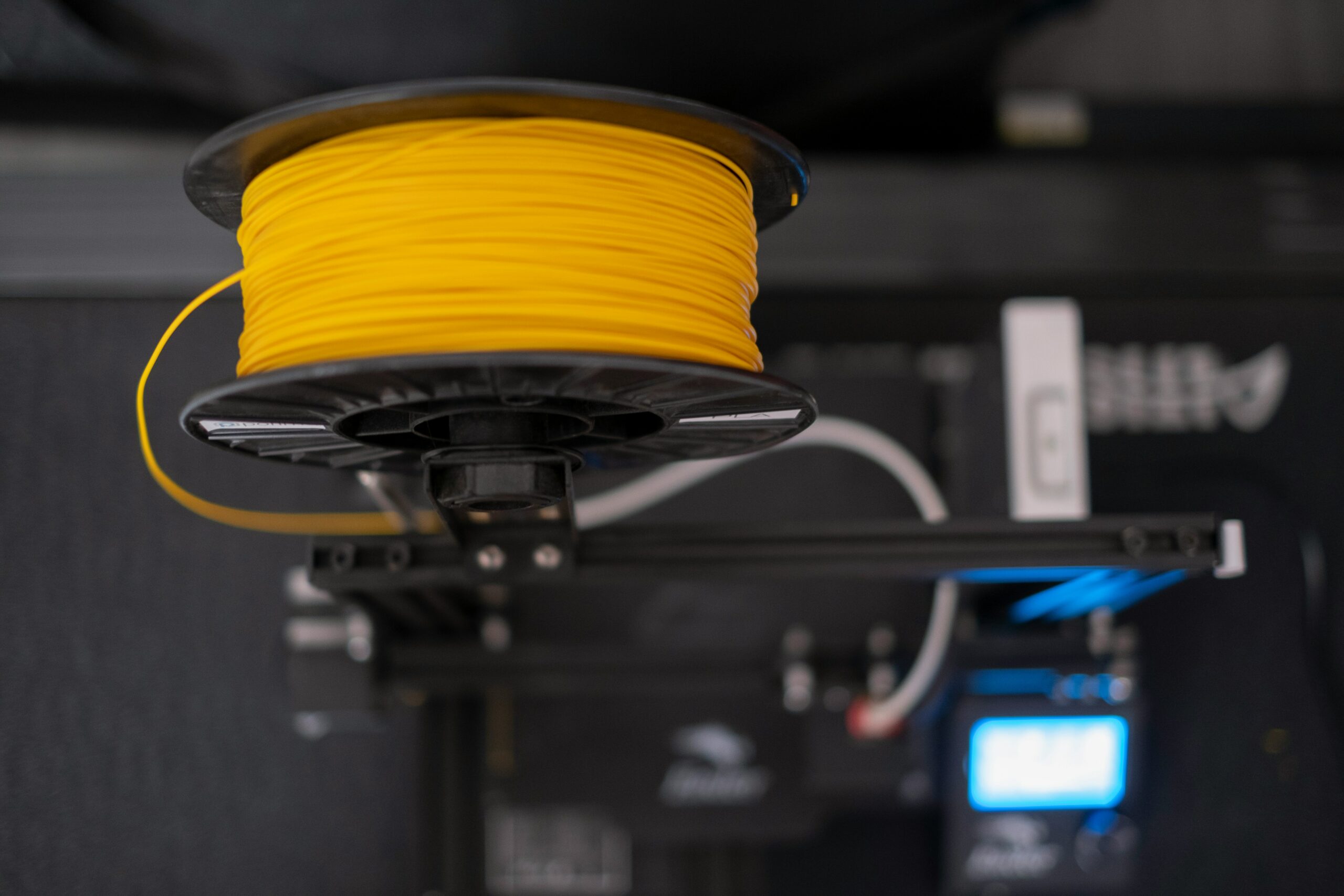

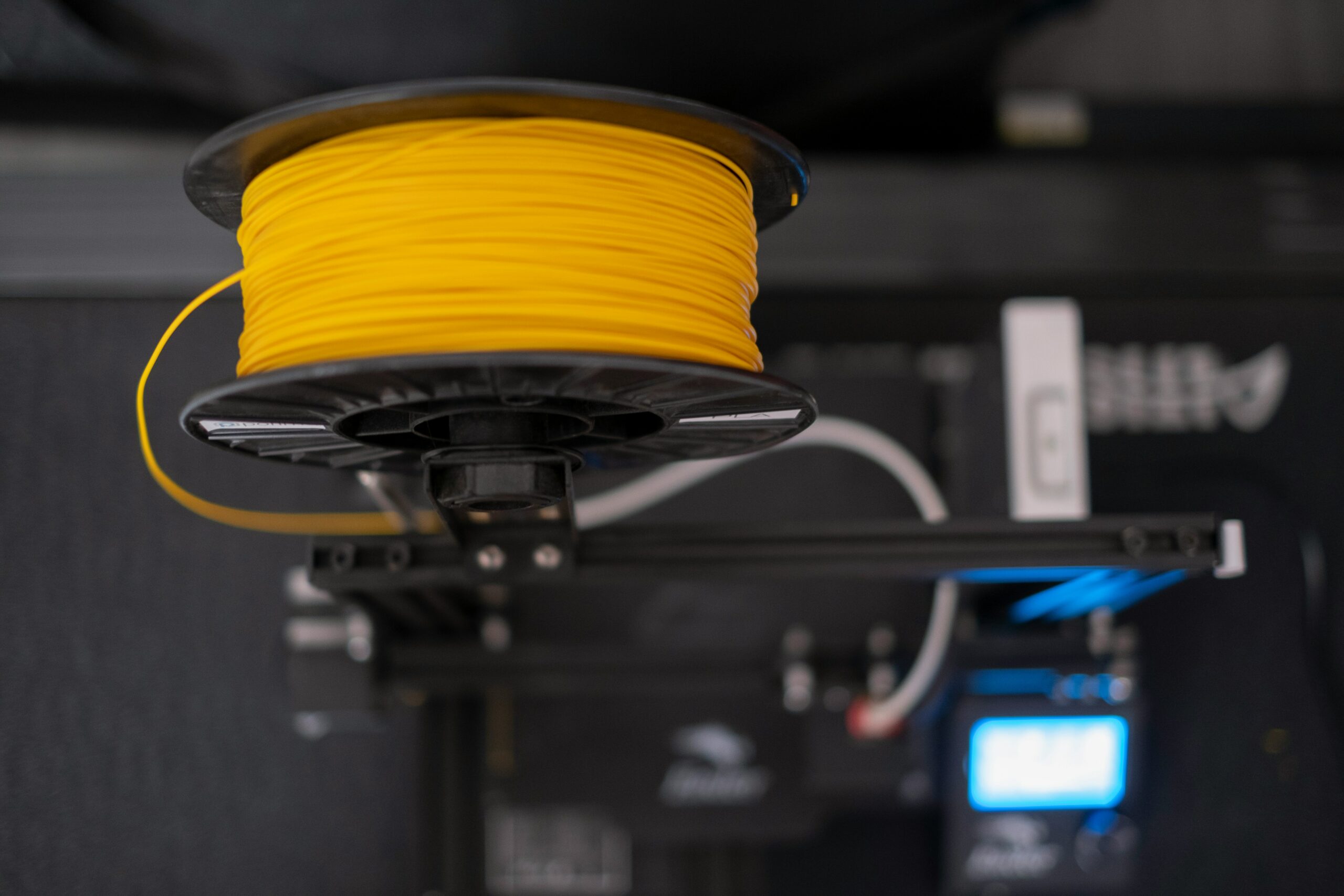

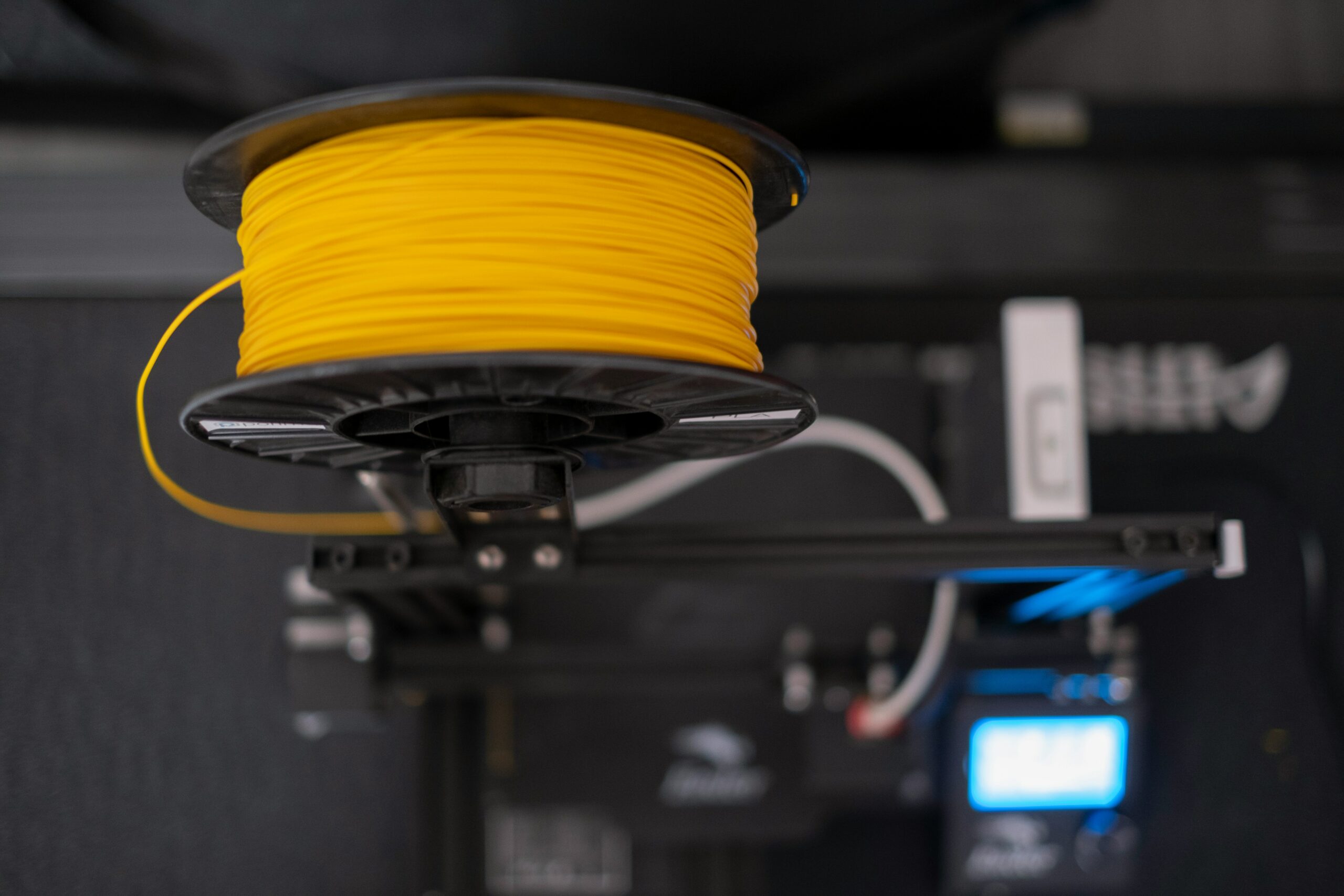

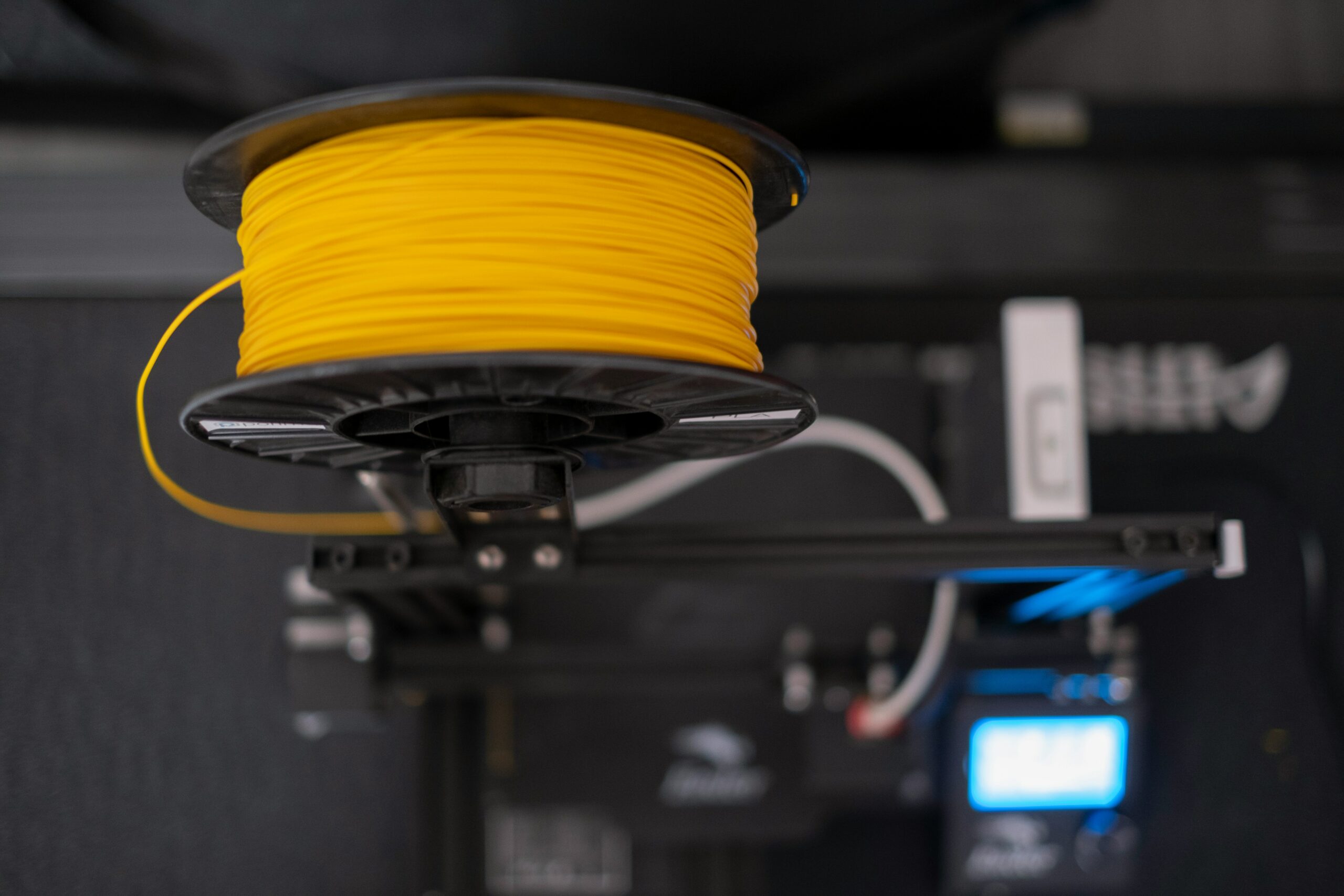

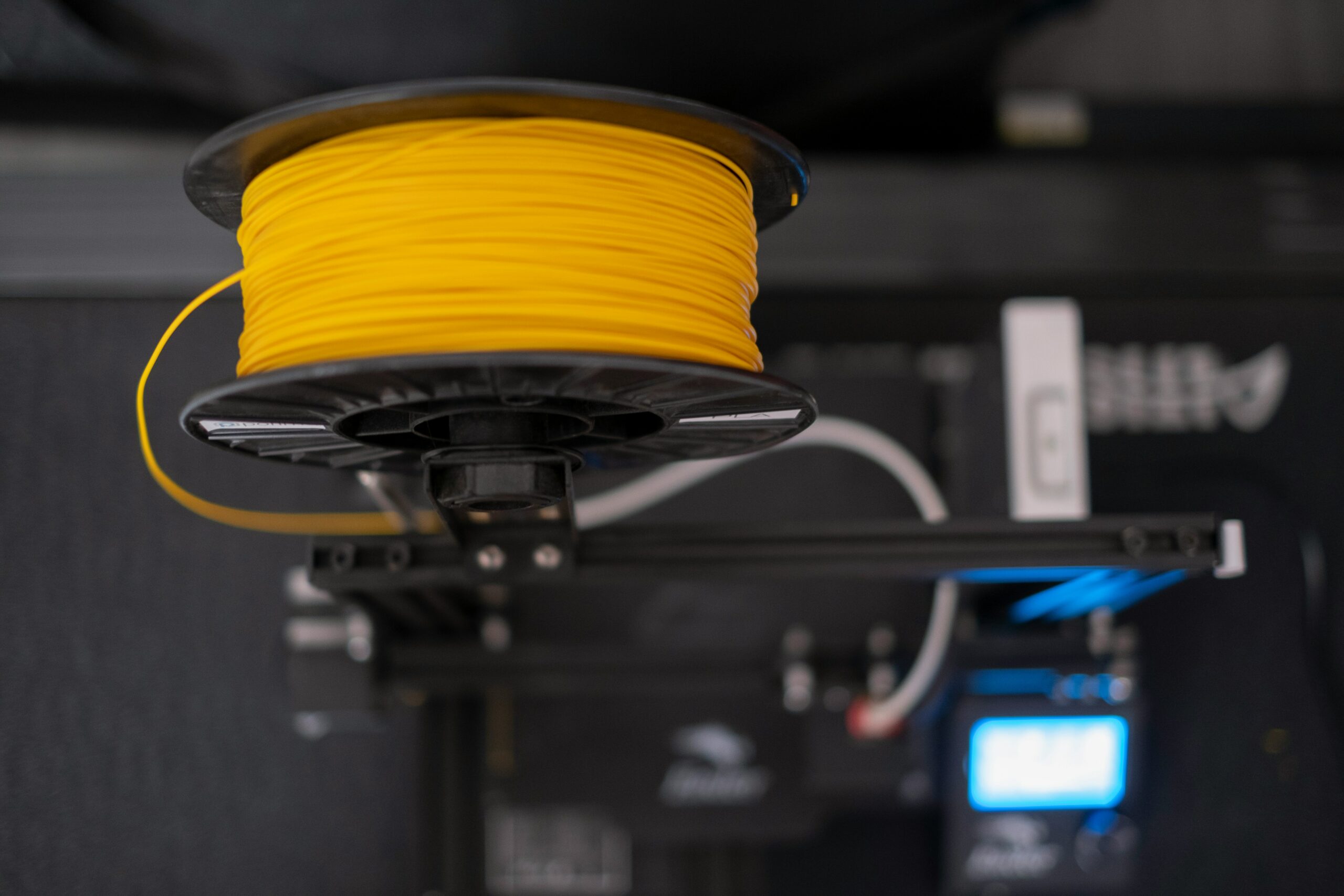

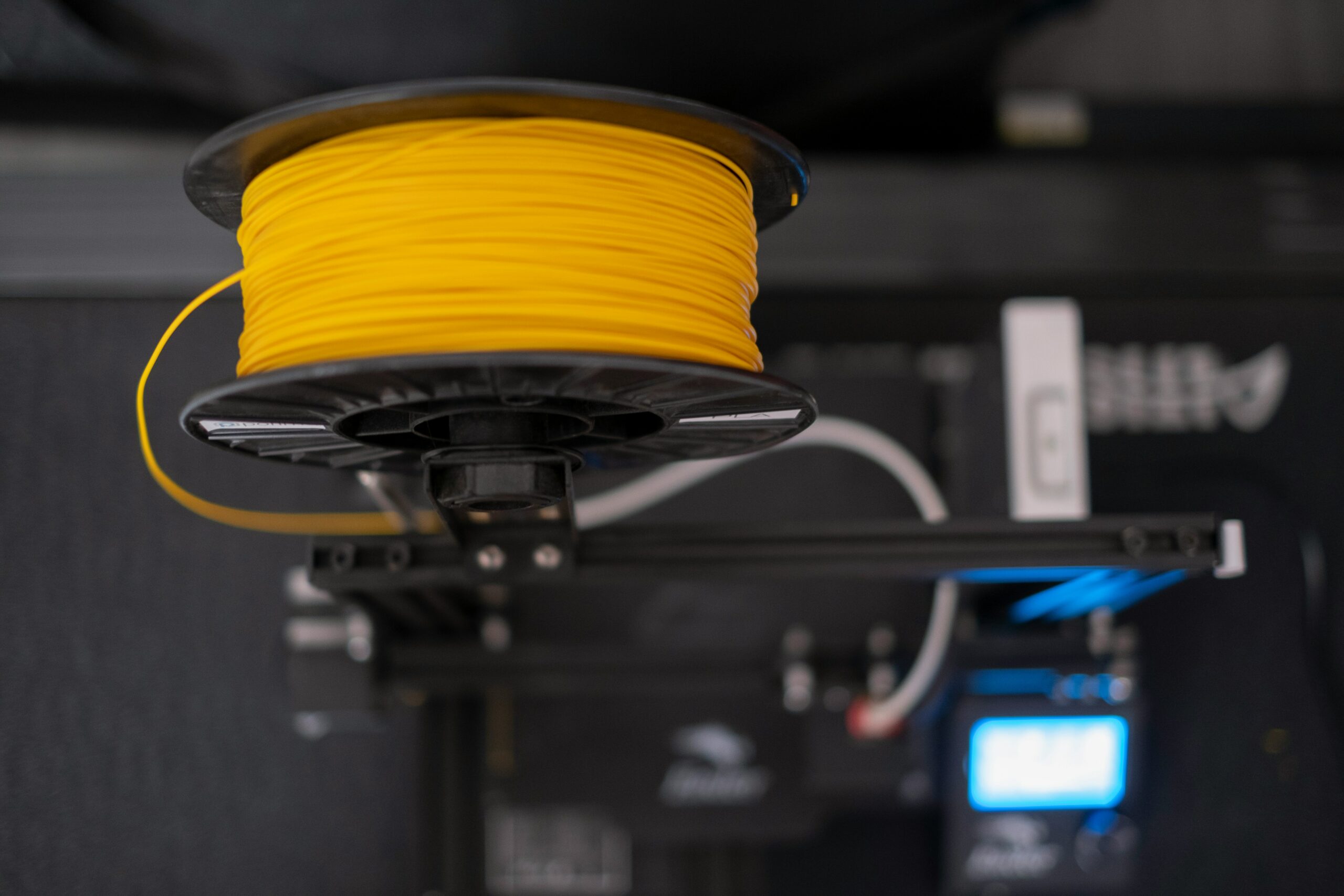

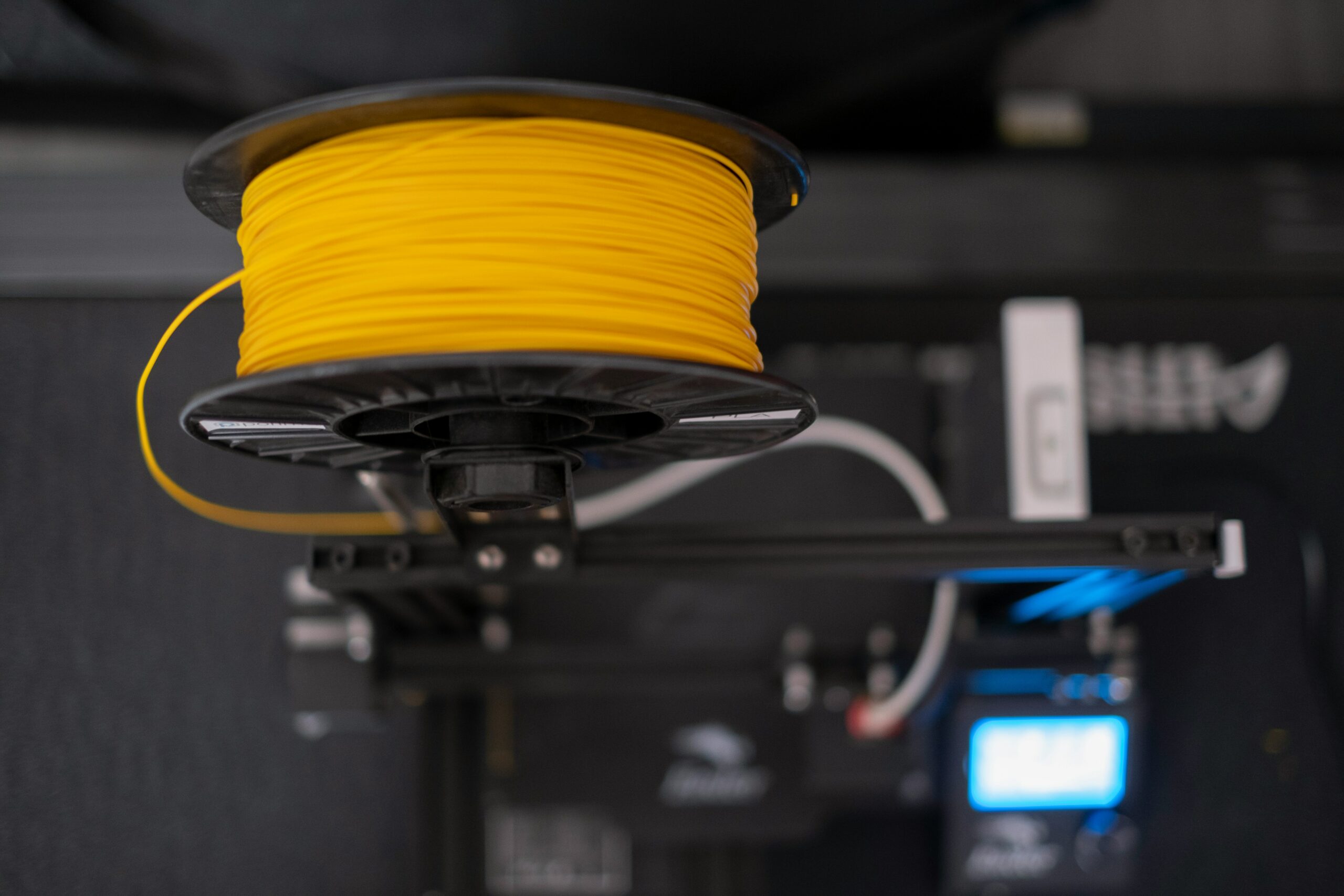

Qu’est ce que le dépôt de fil (FDM) ?

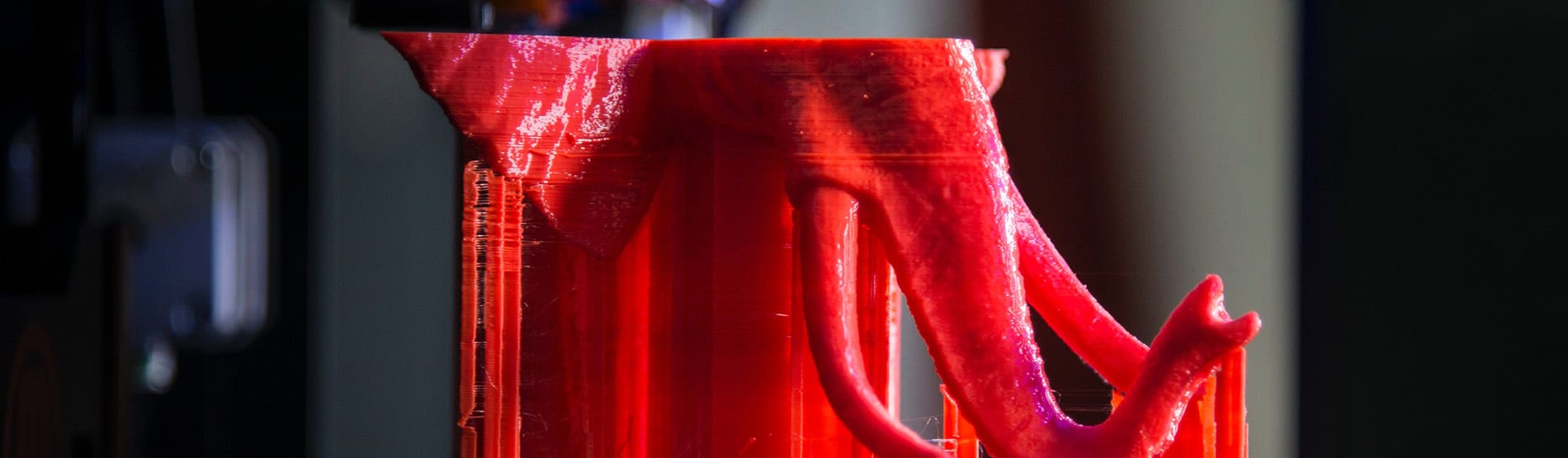

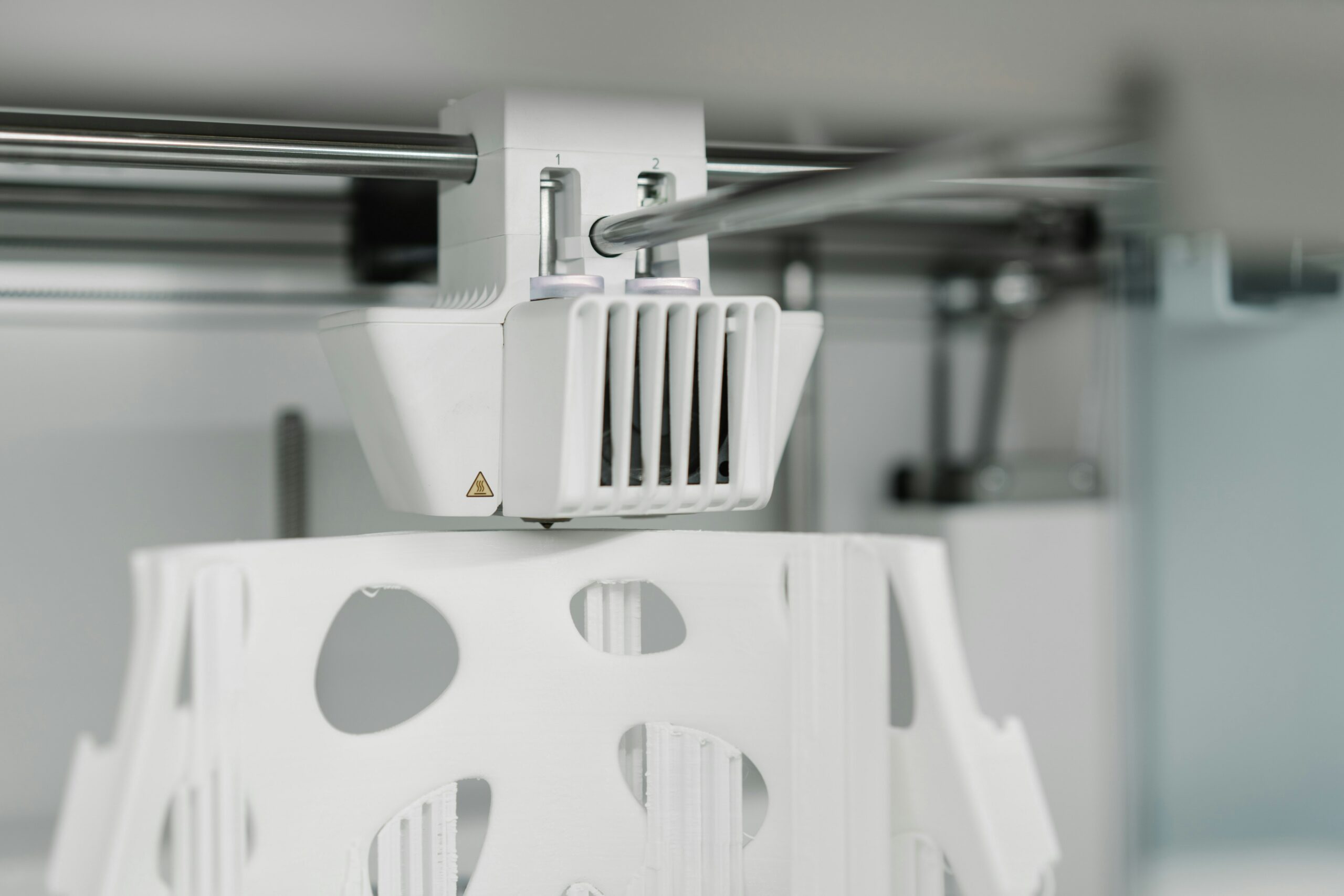

Le dépôt de fil est une méthode d’impression 3D utilisant un fil de matière thermoplastique fondu pour créer des pièces en couches successives.

Le processus de dépôt de fil consiste en un fil de matière thermoplastique chauffé jusqu’à ce qu’il fonde, ce fil est ensuite extrudé par une buse pour former la pièce couche par couche.

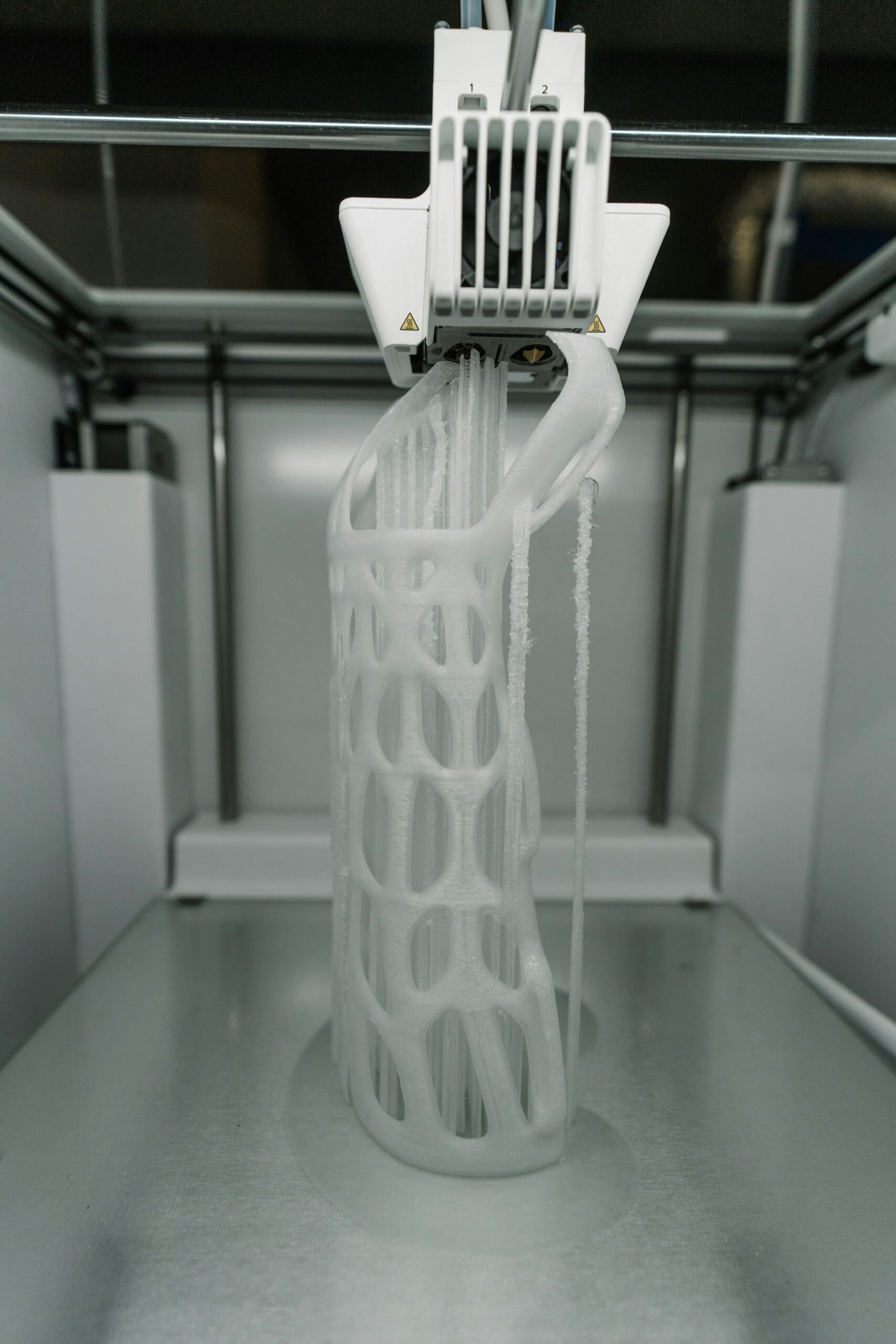

Le dépôt de matière fondue est utilisé dans de nombreux domaines : automobile, aérospatiale, architecture, médical, art…

Etant données ses propriétés, il permet d’imprimer des pièces fonctionnelles, des maquettes et des prototypes.

Les avantages du dépôt de fil (FDM)

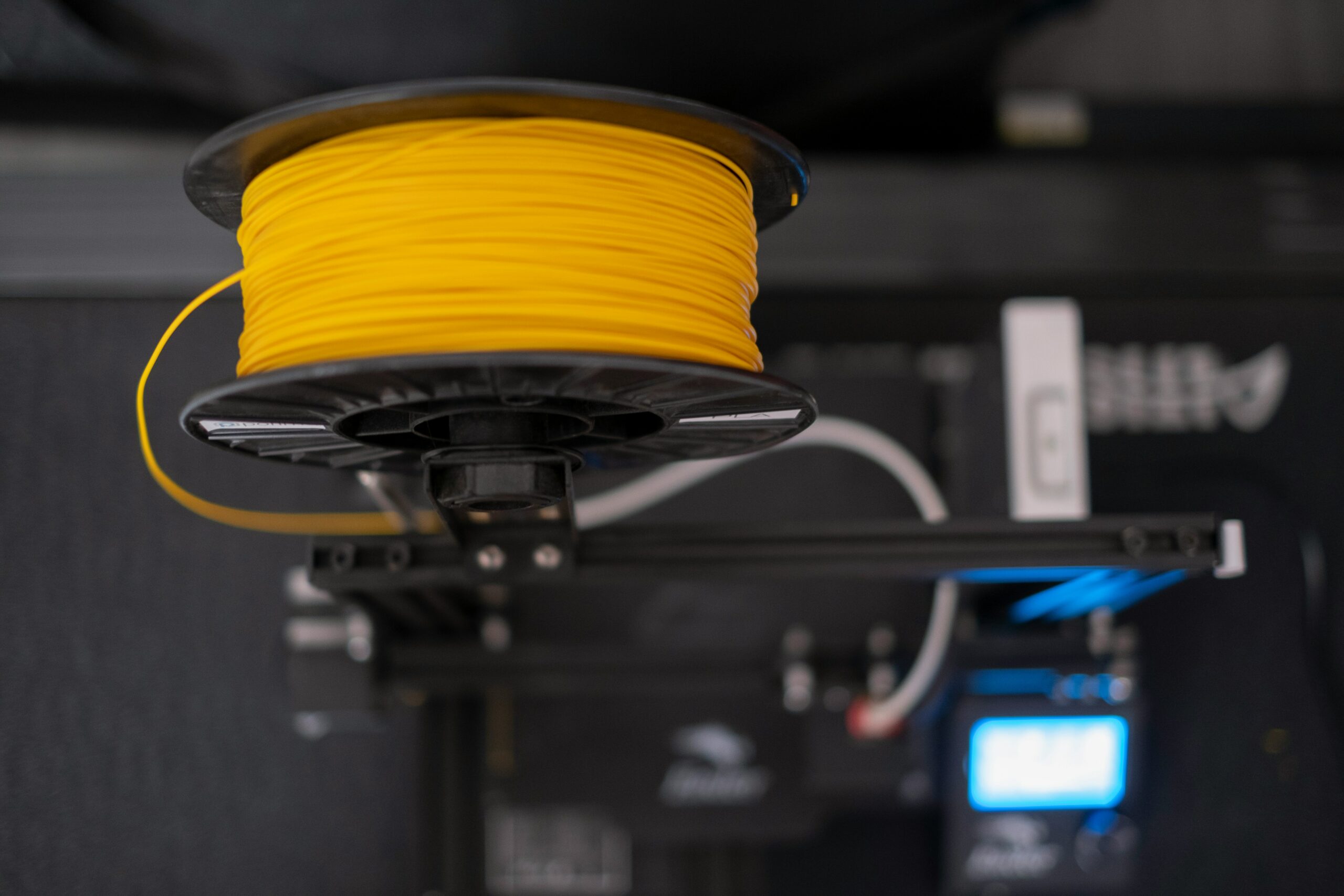

Le FDM est adapté à une variété de filaments thermoplastiques, offrant une polyvalence pour répondre à différents besoins d’application.

Le dépôt de matière fondue est utilisé dans de nombreux domaines : automobile, aérospatiale, architecture, médical, art…

Etant données ses propriétés, il permet d’imprimer des pièces fonctionnelles, des maquettes et des prototypes.

PLA (Dépôt de Fil)

ABS

ABS ESD

ABS MDT

ABS Ignifugé

PP

PA HT 15% Carbone

PC PBT

PET Alimentaire HDGlass

TPU 85 shore

TPU 95 shore

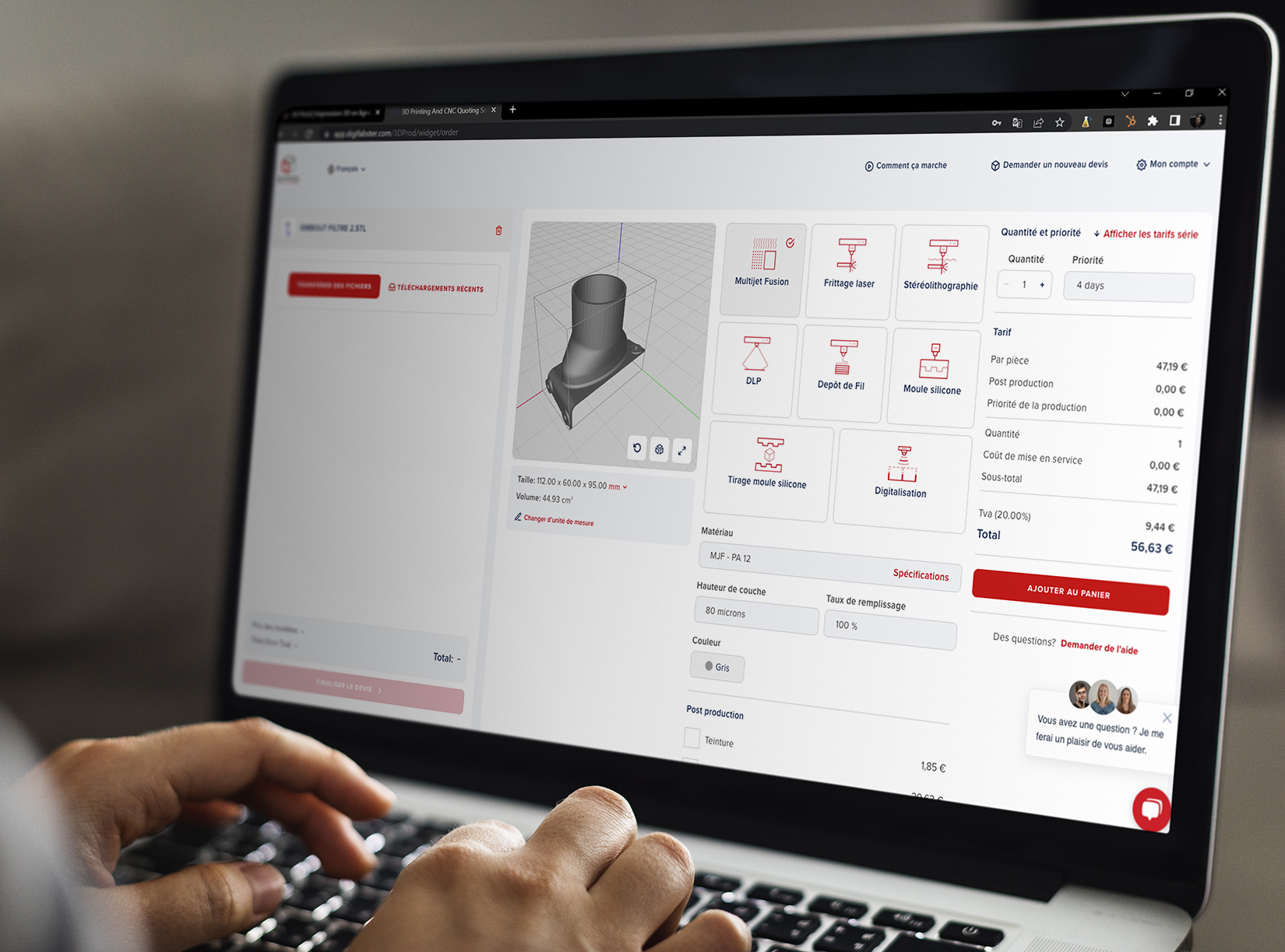

Votre devis en quelques minutes

Choisissez la technologie, le matériau, les finitions et obtenez votre devis instantanément grâce à notre plateforme en ligne.

1. Importez votre fichier CAO

Téléchargez votre fichier 3D (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf ou .zip (avec modèles et textures) fichier n’excédant pas 100 Mb.

2. Choisissez la technologie 3D et les matériaux

Choisissez le filament, les finitions et passez commande en 1 clic.

Nos experts sont à votre disposition pour tous vos projets 3D

FAQ sur le dépôt de fil

Contactez-nous dès maintenant pour discuter de votre projet !

Notre équipe vous recontactera pour concrétiser votre projet !