Les avantages du dépôt de fil

Bonne résistance mécanique

Prix

Respect des géométries

Un matériau

thermoplastique

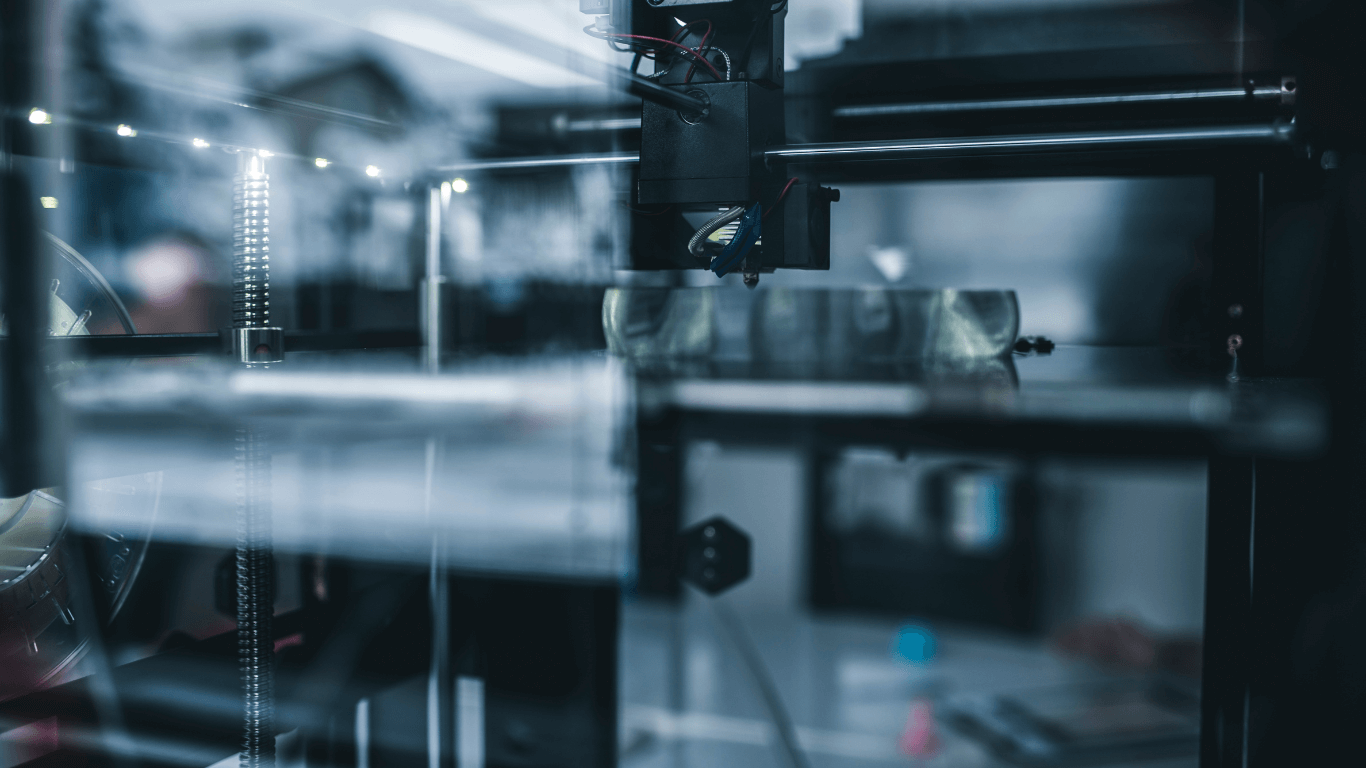

Le dépôt de fil est une technologie qui permet de fabriquer des pièces par ajout de matière. Les matériaux mis en œuvre sont des polymères thermoplastiques.

Fabrication

par extrusion

La machine travaille un peu comme une extrudeuse, elle porte le matériau à son point de fusion pour créer un fil de l’ordre de 0,05 millimètres de diamètre. La buse se déplaçant sur les axes x, y permet de déposer ce fil chaud sur une couche. La plateforme descend entre chaque séquence pour empiler les couches les unes sur les autres.

Pièces fonctionnelles

et maquettes

Le dépôt de matière fondue est utilisé dans de nombreux domaines : automobile, aérospatiale, architecture, médical, art…

Etant données ses propriétés, il permet d’imprimer des pièces fonctionnelles, des maquettes et des prototypes.

Matériaux disponibles

Le matériau disponible pour le dépôt de fil.

Contactez-nous dès maintenant !

Notre équipe vous recontactera pour discuter de vos besoins spécifiques, afin de vous accompagner dans votre projet et vous permettre d'atteindre pleinement vos objectifs.