A 3D printing project, full of good vibes! Discover with us the process and the steps of the project!

STARLAB - The antenna that makes the invisible visible

Specialist in electromagnetic waves, our customer Microwave Vision Group has called upon our services to reproduce one of its measurement systems, the STARLAB antenna. A complex device mixing electronics and mechanics, allowing to visualize and measure the electromagnetic wave emissions emitted by the products.

The STARLAB antenna having an imposing dimension, going from 2 meters in diameter to 36 meters long, Microwave Vision had the will to make a reduced scale model close to the reality, for exhibition and representation purposes.

PROGRESS AND STAGES OF THE PROJECT!

Project evaluation

Supported by the project manager, the project is first evaluated.

Once received, each file will be analyzed and corrected by our design office in order to verify its conformity: minimum thickness, dimensions, suspect elements, faceting, validation of all assembly sets... All this while taking into account sanding and painting to ensure optimal assembly.

In case of non-conformity of your files, we have in-house CAD skills that can assist you in the design, modification and preparation of your files.

A specification is then established to specify the stages of manufacture of the product: the chosen material, the specificities, the arrangement of the elements, the time of manufacture, the possibility or not of being able to dismount the model, as well as the color references to be used at the time of the painting...

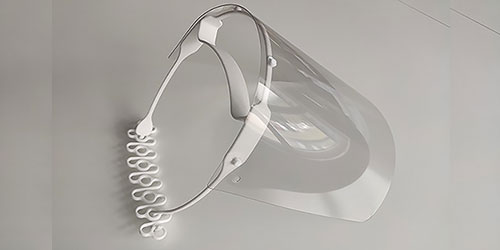

Manufacturing

On our recommendations, the customer chose a manufacturing process using grey stereolithography type PA (Polyamide). This type of material makes it possible to produce complex parts with a high level of detail, perfectly suited to the manufacture of models.

Learn more about stereolithography resins

Post-treatment and light-curing

During the manufacturing process, the liquid resin solidifies on contact with an ultraviolet (UV) laser. The printed parts require post-treatment. They must first be carefully removed from the manufacturing plate, before being cleaned with a solvent to remove uncured resin residues. The parts are then passed through a UV cabin to finalize the polymerization in order to increase the material's resistance as much as possible.

Finishes

Our experts then check the parts to ensure that all the functional dimensions are respected, and an assembly test is then carried out.

In order to make the model even closer to reality, they carry out a surface treatment of the different elements. Finishing is an important phase in the realization of this type of project. A thorough sanding of the parts will guarantee a realistic rendering during the painting (a water sanding with a fine grain).

Learn more about our finishes and completions

Painting

The parts are sent to the paint booth. In order to prepare the colors, the painter refers to the specifications to get the RAL color codes, previously chosen by the customer.

With care, the painting of the elements of the model can then begin. This process allows to give brightness to the parts by using the paint but also the chromium plating or the varnish. Then follows the drying phase before moving on to the assembly phase.

Learn more about stereolithography 3D printing

Assembly of the STARLAB model

The different elements are then assembled and fixed together.

For transportation, we offer specific packaging adapted to any type of project, allowing for safe delivery of packages.

Time of realization all included : 4 days

Learn more about stereolithography